CHEMCAD

User Guide

All material © 2021 Chemstations, Inc.

CHEMCAD User Guide i

CHEMCAD User Guide

Table of Contents

Chapter 1 – Introduction to CHEMCAD

Overview of CHEMCAD and Its Uses .................................................................................................... 1

CHEMCAD Products and Features ..................................................................................................... 3

CHEMCAD Features by Module ......................................................................................................... 4

UnitOps by Module ............................................................................................................................... 5

Chapter 2 – Getting Started with CHEMCAD

Creating a User Support Center Account ............................................................................................... 8

Downloading the Software ....................................................................................................................... 9

Installing the software ............................................................................................................................... 9

Licensing CHEMCAD ............................................................................................................................. 12

Types of CHEMCAD Licenses ........................................................................................................... 12

License Settings ..................................................................................................................................... 12

Updating a License ............................................................................................................................... 14

Getting Help with CHEMCAD .............................................................................................................. 17

Online Help ........................................................................................................................................... 17

The Chemstations Website .................................................................................................................. 17

Contacting Chemstations Technical Support ................................................................................... 17

Chapter 3 – The CHEMCAD Interface

The CHEMCAD Window ....................................................................................................................... 19

The Command Ribbon ......................................................................................................................... 20

The Quick Access Toolbar ................................................................................................................... 20

The Workspace ..................................................................................................................................... 21

The Explorer Pane ................................................................................................................................ 21

The Palette Pane .................................................................................................................................... 23

Table of Contents

ii CHEMCAD User Guide

The Messages Pane ............................................................................................................................... 25

Other CHEMCAD Window Commands .......................................................................................... 26

Customizing the CHEMCAD Screen .................................................................................................... 26

Viewing and Hiding Screen Elements ............................................................................................... 27

Resizing and Moving Items ................................................................................................................ 27

Pinning and Unpinning Panes............................................................................................................ 28

Flowsheet Drawing Tools ....................................................................................................................... 29

The Workspace Group ......................................................................................................................... 30

The Insert Group .................................................................................................................................. 31

The Objects Group ................................................................................................................................ 32

Other Useful Interface Hints .................................................................................................................. 34

Undo and Redo ..................................................................................................................................... 34

Flowsheet Quickview .......................................................................................................................... 34

Adjusting Your View of the Workspace ........................................................................................... 35

Locking Flowsheet Elements .............................................................................................................. 36

Chapter 4 – Working with Simulation Files

About CHEMCAD Simulation Files ..................................................................................................... 39

User Components in CHEMCAD ...................................................................................................... 40

Example Files ........................................................................................................................................ 40

Opening an Existing Simulation ............................................................................................................ 40

Creating a New Simulation .................................................................................................................... 41

Saving a Simulation ................................................................................................................................. 41

Saving Different Cases for the Same Simulation ............................................................................. 42

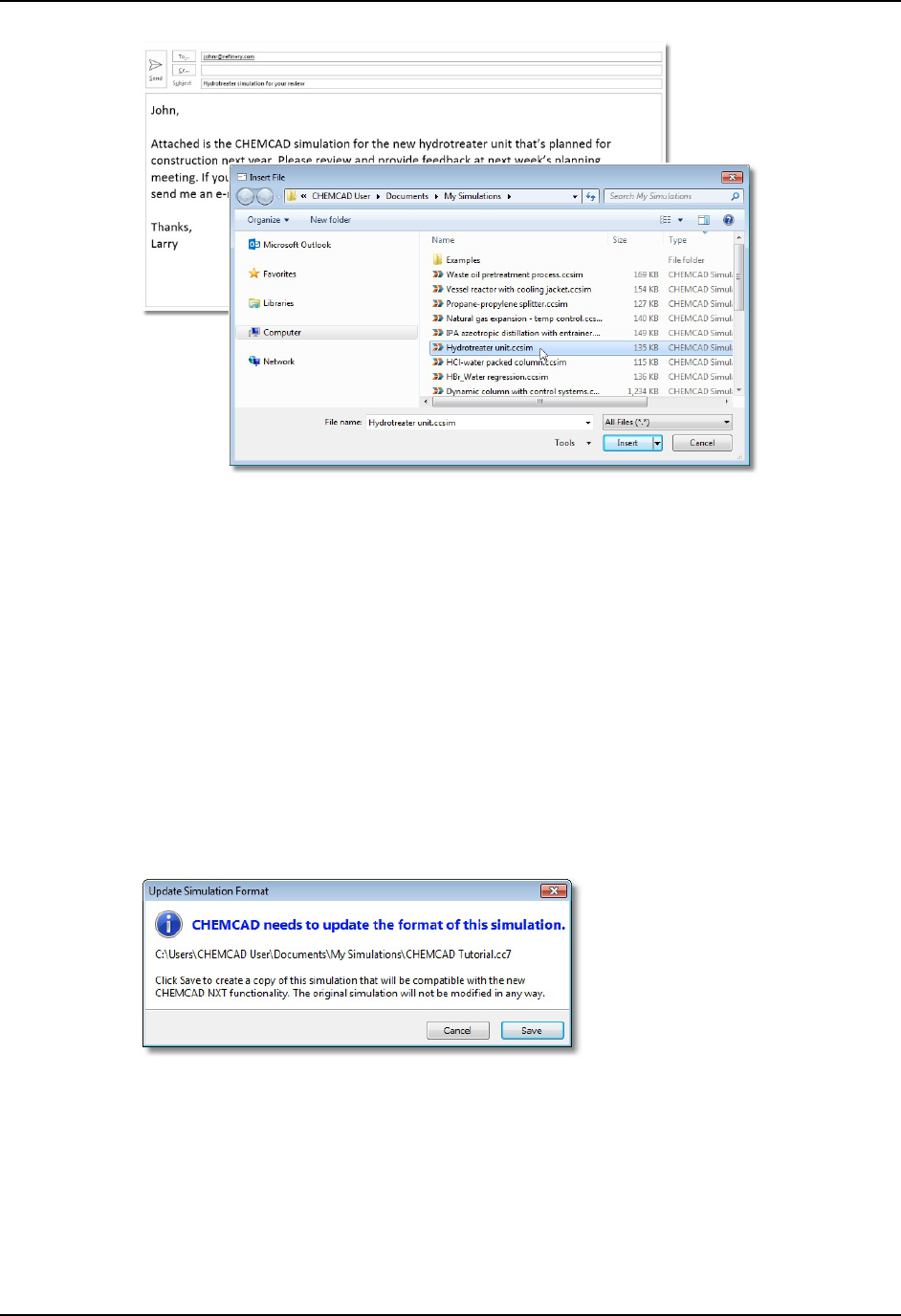

E-mailing a Simulation ............................................................................................................................ 43

Sending from Within CHEMCAD ..................................................................................................... 43

Attaching to an E-mail ......................................................................................................................... 43

Working with CHEMCAD Files from Previous Versions .................................................................. 44

Chapter 5 – Building and Using a Basic Simulation

Starting a New Simulation ...................................................................................................................... 45

Specifying Engineering Units ................................................................................................................. 46

Selecting Chemical Components ........................................................................................................... 46

Finding a Component .......................................................................................................................... 47

Adding a Component .......................................................................................................................... 49

Changing the Order of Selected Components .................................................................................. 49

Removing Items from the Selected Components List ..................................................................... 50

Table of Contents

CHEMCAD User Guide iii

Selecting K-value and Enthalpy Options .............................................................................................. 50

Using the Thermodynamic Suggestions Dialog .............................................................................. 50

Manually Selecting Thermodynamics Settings ................................................................................ 51

Drawing the Flowsheet ........................................................................................................................... 52

Adding UnitOps ................................................................................................................................... 52

Feed and Product Arrows ................................................................................................................... 56

Drawing and Connecting Streams ..................................................................................................... 56

Defining Streams ...................................................................................................................................... 60

Thermodynamic Properties ................................................................................................................ 61

Stream Composition ............................................................................................................................. 61

Total Flow Properties ........................................................................................................................... 61

Specifying Equipment Parameters ........................................................................................................ 62

Running the Simulation .......................................................................................................................... 63

Reviewing the Results ............................................................................................................................. 63

Chapter 6 – Using CHEMCAD for High-Fidelity Modeling

What is high-fidelity modeling? ............................................................................................................ 65

Criteria for High-fidelity Modeling ....................................................................................................... 66

Introduction to Equipment Sizing ......................................................................................................... 66

High-fidelity Modeling and Sizing for Common UnitOps ................................................................ 67

Piping ..................................................................................................................................................... 67

Pumps, Compressors, and Expanders ............................................................................................... 68

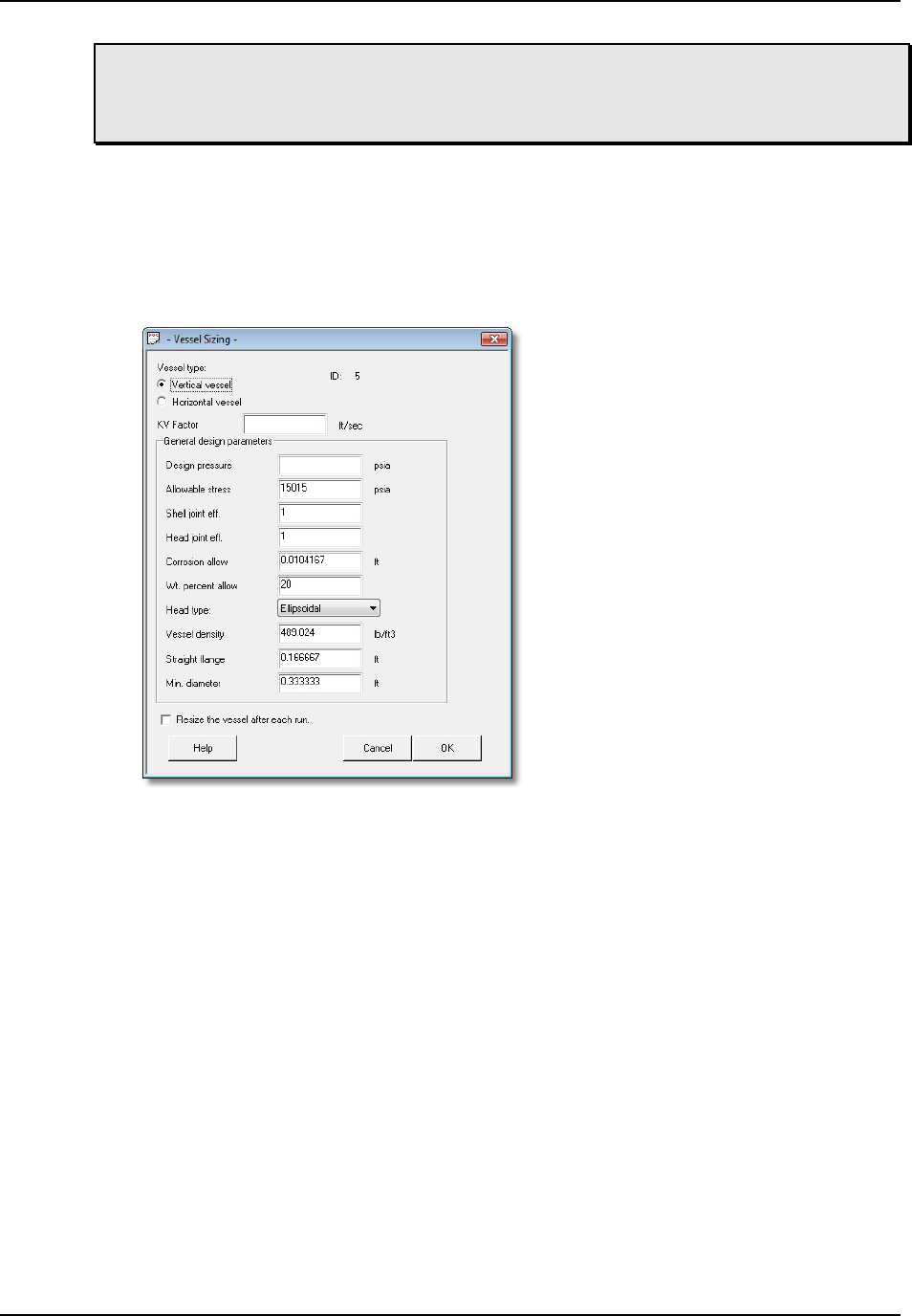

Vessels and Tanks ................................................................................................................................ 68

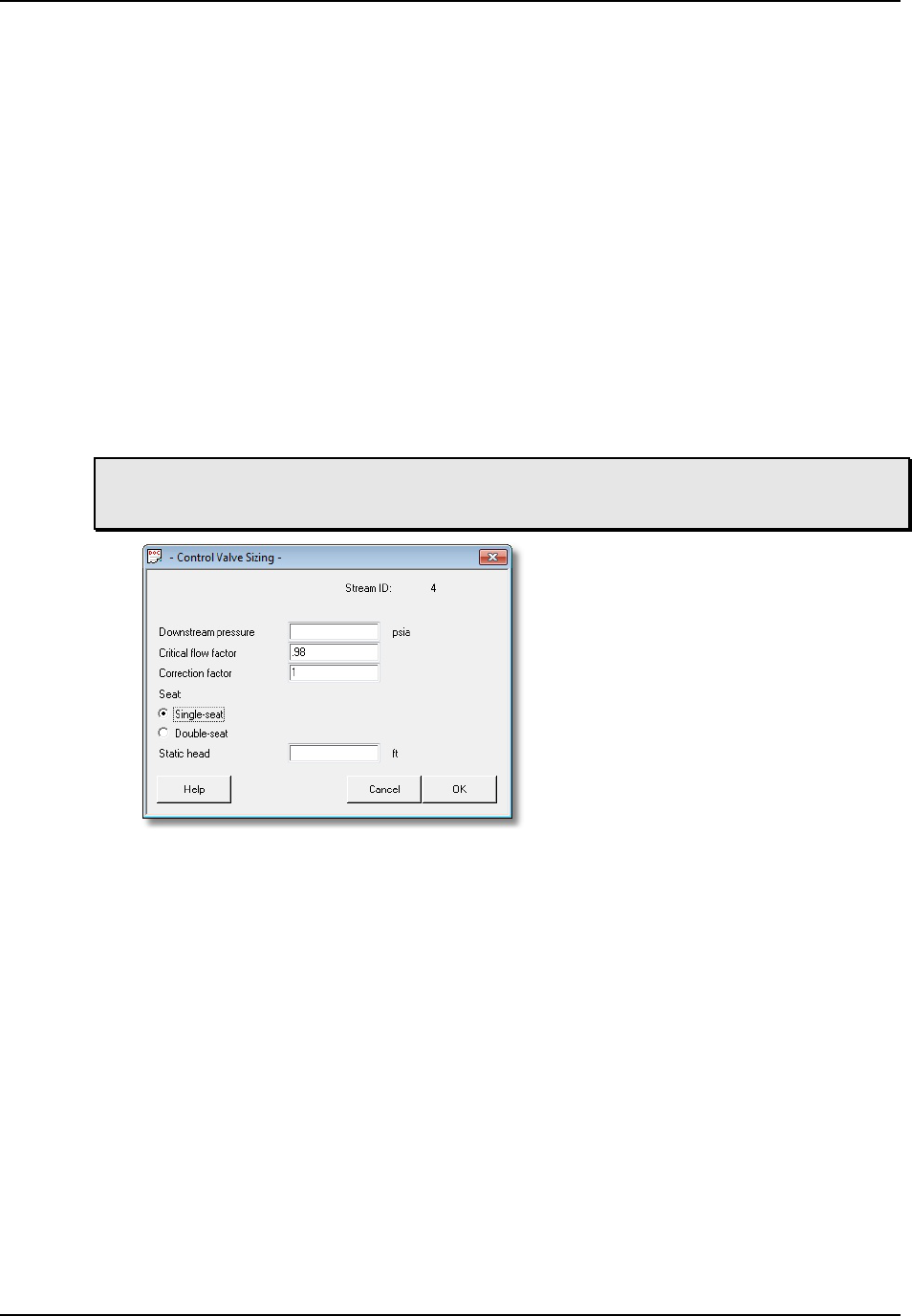

Valves ..................................................................................................................................................... 70

Columns ................................................................................................................................................. 70

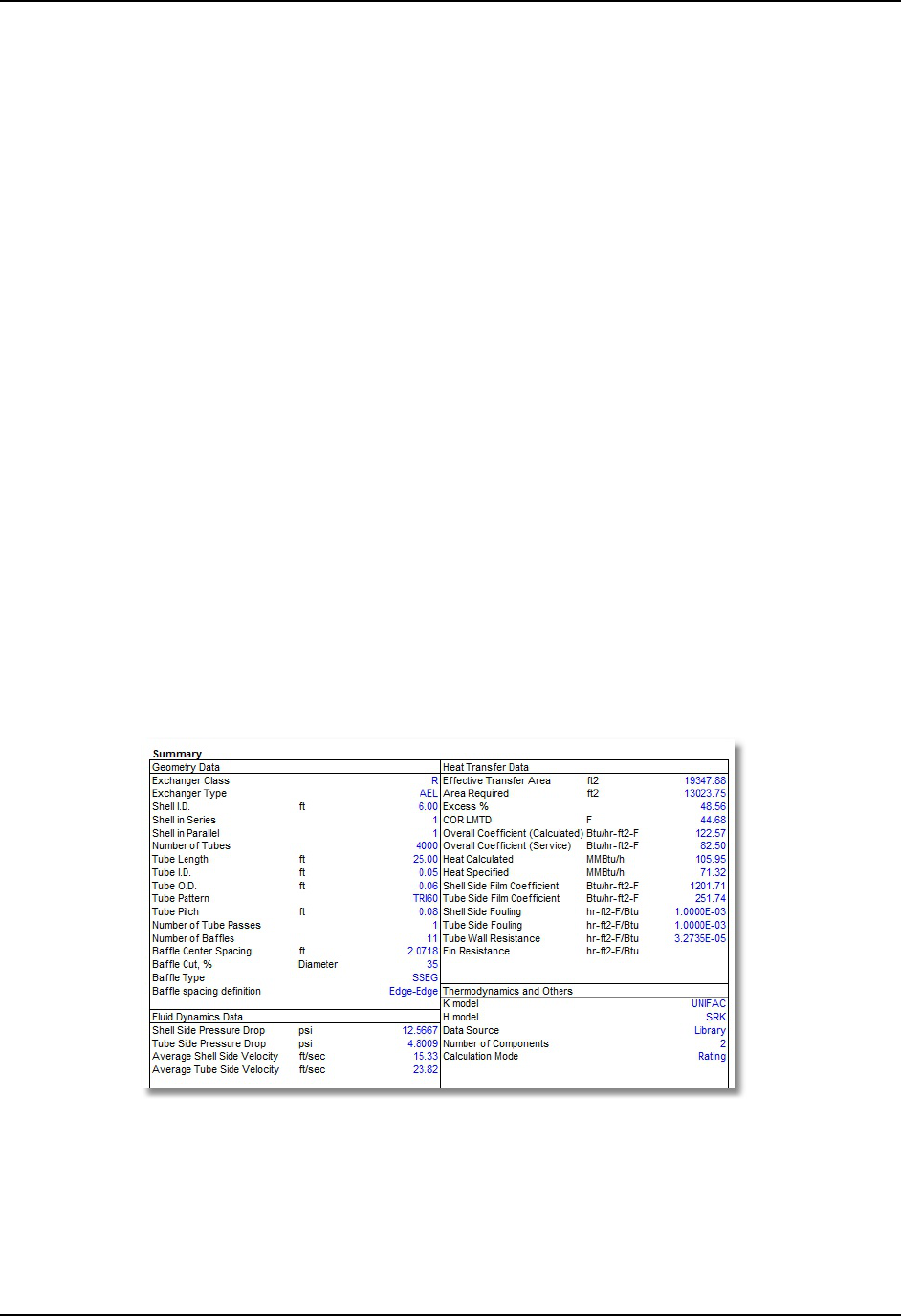

Heat Exchangers ................................................................................................................................... 73

Relief Devices ........................................................................................................................................ 74

Licensing Considerations for High-fidelity Modeling........................................................................ 75

Chapter 7 – Building and Using a Dynamic Simulation

What do we mean by dynamics? ........................................................................................................... 77

Licensing Considerations ........................................................................................................................ 77

Additional Input for Dynamic Operation ............................................................................................ 78

Strategies for Dynamic Simulations ................................................................................................... 79

Setting up Dynamic Operation .............................................................................................................. 79

Switching to Dynamics ........................................................................................................................ 79

Setting the Run Time ............................................................................................................................ 80

Table of Contents

iv CHEMCAD User Guide

Selecting Streams and UnitOps .......................................................................................................... 81

Initial State Settings ................................................................................................................................. 82

Save As Initial State .............................................................................................................................. 82

Reset to Initial State .............................................................................................................................. 83

Running a Dynamic Simulation ............................................................................................................. 83

Run from Initial State ........................................................................................................................... 84

Run from Current State ....................................................................................................................... 84

Run One Step at a Time ....................................................................................................................... 84

Output from Dynamic Simulations ....................................................................................................... 85

Reviewing the Flowsheet Specifications ........................................................................................... 85

Plotting Dynamic Results .................................................................................................................... 85

Text-based Dynamic Reports .............................................................................................................. 86

Chapter 8 – Output and Reports

The Basics: Generating Individual Charts and Reports ..................................................................... 87

The Charts Gallery ................................................................................................................................... 88

Thermodynamic ................................................................................................................................... 88

Stream .................................................................................................................................................... 89

UnitOp ................................................................................................................................................... 90

Dynamic ................................................................................................................................................. 90

User......................................................................................................................................................... 91

Chart Tab Commands ............................................................................................................................. 91

Edit Group ............................................................................................................................................. 92

Chart Settings Group ........................................................................................................................... 92

X Axis, Y Axis, Secondary Y Axis, and Tertiary Y Axis Groups.................................................... 93

A Axis, B Axis, and C Axis Groups ................................................................................................... 94

Window Group ..................................................................................................................................... 94

Adding Chart Data Manually with the User Series Feature .............................................................. 94

Adding a New User Series .................................................................................................................. 94

Displaying a User Series on a Chart .................................................................................................. 95

Editing User Series Values .................................................................................................................. 95

Importing Values for a User Series .................................................................................................... 95

Adding Data Points to a Ternary Chart ............................................................................................ 96

Deleting a User Series .......................................................................................................................... 96

The Reports Gallery ................................................................................................................................. 96

Stream .................................................................................................................................................... 97

UnitOp ................................................................................................................................................... 98

Table of Contents

CHEMCAD User Guide v

Distillation ............................................................................................................................................. 98

Flowsheet ............................................................................................................................................... 99

Dynamic ............................................................................................................................................... 100

UnitOp and Stream Groups .................................................................................................................. 100

Creating a Group ................................................................................................................................ 100

UnitOp and Stream Group Commands .......................................................................................... 101

Choosing Groups in the Select Streams and Select UnitOp Dialogs ........................................... 102

Report Viewer Setup .............................................................................................................................. 102

Printing CHEMCAD Reports and Charts .......................................................................................... 103

Consolidated Reports and the CHEMCAD Report Writer .............................................................. 103

Choosing and Ordering Report Sections ........................................................................................ 104

Selecting Flowsheet Elements ........................................................................................................... 105

Formatting Report Sections ............................................................................................................... 105

Naming the Report and Choosing a Destination ........................................................................... 106

Selecting a Report Viewer for Consolidated Reports .................................................................... 107

Property Sets ........................................................................................................................................... 107

Built-in Property Sets ......................................................................................................................... 107

User-created Property Sets ................................................................................................................ 107

Different Sets for Different Purposes ............................................................................................... 107

The Property Set Preferences Dialog ............................................................................................... 108

Active Set Designations ..................................................................................................................... 109

Editing a Property Set ........................................................................................................................ 109

Creating a New Property Set ............................................................................................................ 109

Copying an Existing Property Set .................................................................................................... 110

Format Tab Options ........................................................................................................................... 111

Resetting Built-in Property Sets ........................................................................................................ 111

Deleting a User-added Property Set ................................................................................................ 111

Using the Property Set Library ......................................................................................................... 111

Sharing Property Sets with Other CHEMCAD Users ................................................................... 113

Creating Process Flow Diagrams ......................................................................................................... 113

Adding Flowsheet Databoxes ........................................................................................................... 113

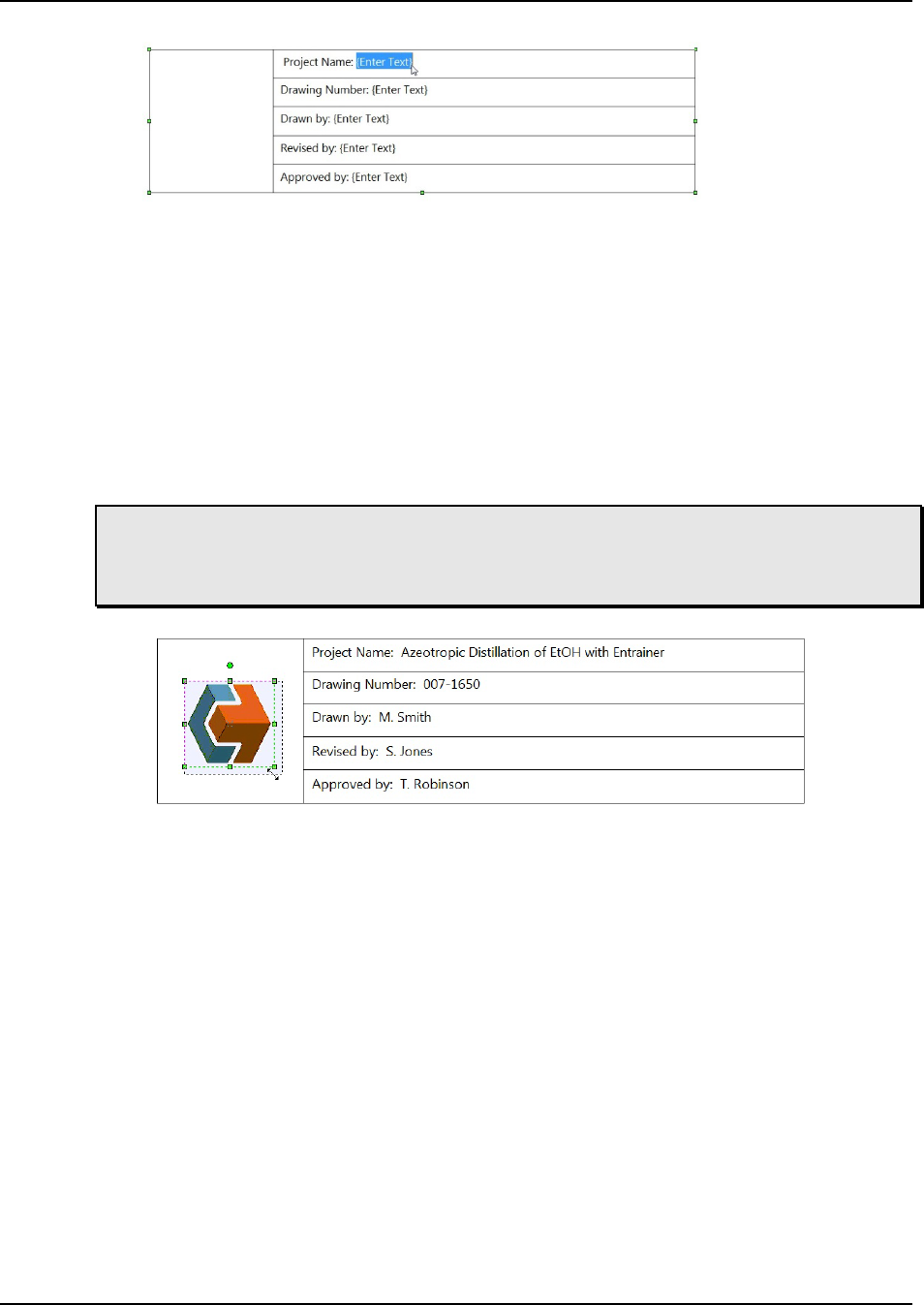

Using Title Blocks ............................................................................................................................... 117

Using the Layers Feature for Selective Viewing and Printing ..................................................... 119

Printing a Process Flow Diagram ..................................................................................................... 122

Table of Contents

vi CHEMCAD User Guide

Chapter 9 – Customizing CHEMCAD

Flowsheet Templates ............................................................................................................................. 123

Creating a Template ........................................................................................................................... 124

Viewing a Template’s Properties ..................................................................................................... 124

Applying a Template ......................................................................................................................... 124

Renaming or Deleting a Template ................................................................................................... 125

Creating Custom Components ............................................................................................................. 125

Adding a Single Component ............................................................................................................ 125

Defining a Petroleum Assay Range ................................................................................................. 129

Importing a Neutral File .................................................................................................................... 130

Customizing Thermodynamics ............................................................................................................ 130

Creating a Custom K-value or Enthalpy Model ............................................................................ 131

Creating a Custom Mixing Rule ....................................................................................................... 132

Visual Basic Applications (VBA) ......................................................................................................... 132

Defining a Reaction, Mixing Rule, or UnitOp ................................................................................ 132

Using a VBA-defined Reaction ......................................................................................................... 133

Using a VBA-defined Mixing Rule .................................................................................................. 134

Using a VBA-defined UnitOp ........................................................................................................... 134

Customizing UnitOp Palettes ............................................................................................................... 135

Creating a Custom Palette ................................................................................................................. 135

Copying an Existing Palette .............................................................................................................. 135

Renaming a Palette ............................................................................................................................. 136

Using a Custom Color Scheme to Change UnitOp Symbol Colors ............................................. 136

Resetting Palettes to Default Configuration ................................................................................... 137

Creating Custom UnitOp Symbols ...................................................................................................... 137

Starting the UnitOp Designer ........................................................................................................... 138

Drawing and Sizing the Symbol ....................................................................................................... 138

Saving the Symbol Drawing ............................................................................................................. 139

Adding and Locating Ports ............................................................................................................... 139

Specifying Ports .................................................................................................................................. 139

Publishing the UnitOp Symbol ........................................................................................................ 140

Time-saving Strategies for Creating Multiple Custom Symbols ................................................. 141

Creating Custom UnitOps .................................................................................................................... 143

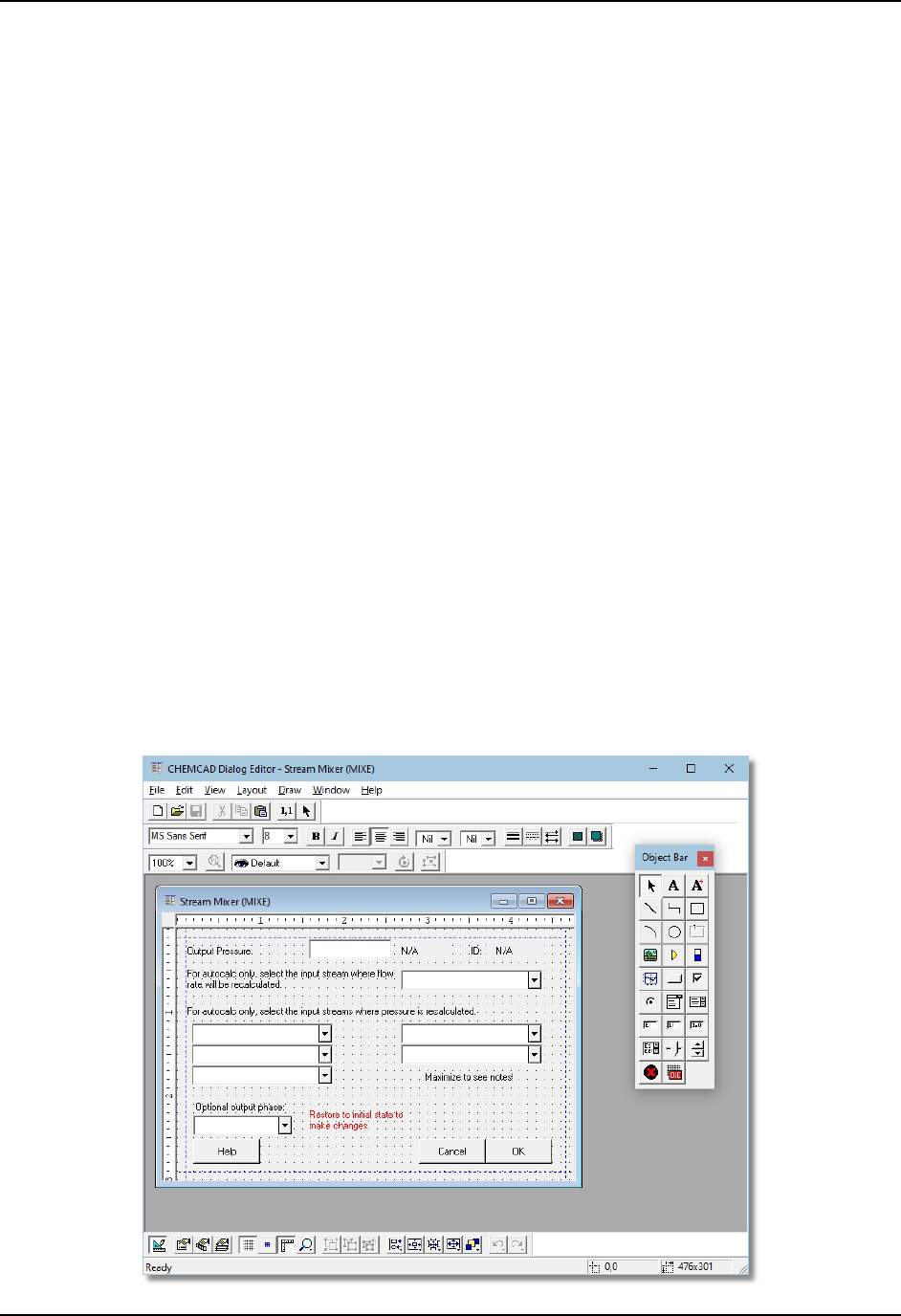

Creating a Custom UnitOp Dialog Box ........................................................................................... 144

Customized Costing Calculations ....................................................................................................... 145

Table of Contents

CHEMCAD User Guide vii

Chapter 10 – Data Interfaces

Excel Data Mapping .............................................................................................................................. 151

Creating an Excel Data Map ............................................................................................................. 152

Data Map Execution Rules ................................................................................................................ 155

Creating Excel UnitOps ......................................................................................................................... 157

Specification Sheets ................................................................................................................................ 157

Using CHEMCAD as an OPC Server .................................................................................................. 158

OPC Applications ............................................................................................................................... 158

OPC Compliance ................................................................................................................................ 159

Enabling CHEMCAD as an OPC Server ......................................................................................... 159

Reading and Writing Values to CHEMCAD Using OPC ............................................................. 159

OPC Server Operations ..................................................................................................................... 160

CHEMCAD OPC Namespace ........................................................................................................... 160

COM Interfaces ....................................................................................................................................... 161

Connecting Excel and CHEMCAD: A Simple COM Interface ..................................................... 161

Table of Contents

viii CHEMCAD User Guide

CHEMCAD User Guide 1

Chapter 1

Introduction to CHEMCAD

Welcome to CHEMCAD, a powerful and effective software tool for chemical process

simulation. Whether you’re a new or experienced CHEMCAD user, you’ll appreciate

the program’s user-friendly, feature-rich interface. Creating flowsheets and running

simulations is fast and easy with CHEMCAD, and the program is highly

customizable to fit your needs and the way you work.

This User Guide will help you get up and running with CHEMCAD, from

installation and licensing to details on using dynamics and data interfaces.

Overview of CHEMCAD and Its Uses

Today’s chemical processing industry (CPI) faces numerous challenges:

unpredictable fuel and feedstock costs, reduced engineering staff, shorter product

life cycles, increased global competition, and increased regulation. These challenges

require that CPI companies seek out and use the best tools to increase productivity

and improve engineering decisions.

CHEMCAD is a powerful and flexible chemical process simulation environment,

built around three key values of innovation, integration, and open architecture.

These values create important advantages for CHEMCAD users:

• The latest chemical engineering techniques at your fingertips

• All functionality united in a single software environment

• Seamless connection to the chemical engineering computing environment, with

links to tools such as MS Excel and Word and interfaces such as COM, DCOM,

OPC, CAPE-OPEN, and XML

Introduction to CHEMCAD

2 CHEMCAD User Guide

CHEMCAD combines a state-of-the-art graphical user interface (GUI), an

extensive chemical component database, a large library of thermodynamic data, and

a library of the most common unit operations to give users the ability to provide

significant and measurable returns on their investment. In addition, the program is

customizable to allow custom chemicals, thermodynamics, unit operations,

calculations, and reporting—all ingredients for a powerful user experience.

CHEMCAD is capable of modeling continuous, batch, and semi-batch processes,

and it can simulate both steady-state and dynamic systems. This program is used

extensively around the world for the design, operation, and maintenance of chemical

processes in a wide variety of industries, including oil and gas exploration,

production, and refining; gas processing; commodity and specialty chemicals;

pharmaceuticals; biofuels; and process equipment manufacturing.

Within all these industries, chemical engineers work every day with CHEMCAD

to address a variety of challenges:

• Initial design of new processes

• Optimization or de-bottlenecking of existing processes

• Performance monitoring of processes

• Design and rating of process equipment such as vessels, columns, heat

exchangers, piping, valves, and instrumentation

• Evaluation of safety relief devices

• Heat exchanger sizing

• Pressure and flow balancing of complex piping networks

• Reconciliation of plant data

• Economic comparisons of process alternatives

• Advanced process control (APC), including model predictive control (MPC),

real-time optimization (RTO), and operator training systems (OTS)

• Scale-up of processes from lab-scale to pilot-scale, and from pilot-scale to full-

scale

• Binary interaction parameter (BIP) regression from process or lab data

• Batch reaction rate regression from process or lab data

No matter how complex your process, CHEMCAD is capable of delivering the

results you need to stay competitive in an increasingly fast and fluid global market.

Easy to learn and highly customizable, CHEMCAD can put future-proof solutions

within easy reach of your engineering staff.

Getting Started with CHEMCAD

CHEMCAD User Guide 3

CHEMCAD Products and Features

The CHEMCAD suite consists of several modules that serve specific purposes.

Depending on your particular needs, you may have purchased some or all of these

modules. The following are brief descriptions of the various CHEMCAD modules

and their most common uses.

CC-STEADY STATE

The main CHEMCAD product, known as CC-STEADY STATE, enables you to

design new processes, rate existing processes, and optimize processes in steady state.

CC-DYNAMICS

The module known as CC-DYNAMICS makes it possible to design new and rate

existing processes using a dynamic simulation. This module is fully integrated with

CHEMCAD to make switching between steady state and dynamics easy and

intuitive. Using CC-DYNAMICS, you can easily simulate everything from simple

vessel accumulation to complex control systems on columns. This module also

provides tools for simulation of continuous stirred-tank reactors (CSTRs), including

complex reaction rate and pressure calculation.

CC-BATCH

The CC-BATCH product enables you to design, rate, or optimize a batch distillation

column. CC-BATCH includes a scheduling interface to allow an “operation step”

approach to simulation of batch columns.

CC-THERM

The CC-THERM product lets you design a single heat exchanger, or vet a vendor’s

heat exchanger design. It is also ideal for customers who want to rate existing

exchangers in new service, or to perform calculations on hypothetical situations. CC-

THERM can simulate shell-and-tube, air-cooled, plate-and-frame, and double-pipe

exchangers. Full integration with CHEMCAD makes it possible to calculate exit

conditions from exchanger geometry for high-fidelity simulations.

CC-SAFETY NET

The CC-SAFETY NET product provides the capability to design or rate piping

networks and safety relief devices and systems, in both steady-state and dynamic

systems. The steady-state features of CC-SAFETY NET are included with CC-

STEADY STATE. This product enables users to make simultaneous flow- and

pressure-balanced simulations—even in reverse-flow situations—for single- or

multi-phase flow.

CC-FLASH

The CC-FLASH module provides physical property and phase equilibrium data, as

well as property prediction and regression. CC-FLASH is a subset of CC-STEADY

STATE, and is meant for customers who do not need full flowsheet simulation tools.

Introduction to CHEMCAD

4 CHEMCAD User Guide

CHEMCAD Features by Module

The following matrix lists the features associated with each component of the

CHEMCAD suite. For a more detailed explanation, or to inquire about a particular

component or feature, please contact Chemstations or your CHEMCAD distributor

(see complete contact information at www.chemstations.com).

CC-

STEADY STATE

CC-

DYNAMICS

CC-BATCH

CC-THERM

CC-

SAFETY NET

CC-FLASH

VB/COM/OPC/Data Map

Sensitivity/optimization

Sizing (line/valve/orifice/vessel)

Run steady state

Run dynamics

Run recycles

Costing

Reconciliation

Sizing columns

Sizing heat exchangers

Economics

Reports (incl. Excel)

DIERS

CO

2

solid

Hydrates

Depress

TOC/COD

Pure regression

BIP regression

Electrolyte regression

Rate regression

Units calculator

Execute parser

Environmental report

Simple calculator

Spec sheet

Getting Started with CHEMCAD

CHEMCAD User Guide 5

UnitOps by Module

The availability of certain unit operations, or UnitOps, in CHEMCAD simulations is

a function of which modules you have licensed. The following matrix lists all

available UnitOps and the CHEMCAD modules associated with them.

CC-

STEADY STATE

CC-

DYNAMICS

CC-BATCH

CC-THERM

CC-

SAFETY NET

CC-FLASH

Baghouse filter

Batch column

Calculator

Centrifuge

Component separator

Compressor

Control valve

Controller

Crusher/grinder

Crystallizer

Cyclone

Divider

Electrostatic precipitator

Equilibrium reactor

Excel unit

Expander

Fired heater

Flash

Gibbs reactor

Heat exchanger

Hydrocyclone

Kinetic reactor

Liquid/liquid extractor

LNGH exchanger

Loop

Membrane

Mixer

Introduction to CHEMCAD

6 CHEMCAD User Guide

CC-

STEADY STATE

CC-

DYNAMICS

CC-BATCH

CC-THERM

CC-

SAFETY NET

CC-FLASH

Node

PID controller

Pipe simulator

Polymer reactor

Pump

Ramp controller

Relief device

Run subflowsheet META unit

SCDS distillation column

Screen

Sedimentator

Shortcut column

Solids dryer

Solids washer

Stoichiometric reactor

Stream reference

Tank

Time delay

Time switch

Tower distillation column

Tower plus distillation column

User-added module

Vacuum filter

Valve

Venturi scrubber

Vessel

Vessel reactor

CHEMCAD User Guide 7

Chapter 2

Getting Started with CHEMCAD

To start using CHEMCAD, you’ll need to obtain the software, install it on your

computer, and set up a valid software license. This chapter provides step-by-step

instructions for these tasks.

Before you begin, please ensure that your PC meets the recommended system

requirements, as listed below. It’s also a good idea to find out whether your copy of

CHEMCAD will rely on a

network license; if it will, make

sure to ask your network

administrator for all the

information that you’ll need

when installation is complete

and it’s time to set up

licensing.

If you’ll be using a

hardware dongle to license

CHEMCAD, make sure the

dongle is inserted into a USB

port before you attempt to run

the program.

To obtain the CHEMCAD

installation file, you’ll need a live Internet connection and a web browser. You can

either download the file directly onto the system where you plan to install

CHEMCAD, or download the file and place it onto a portable drive for installation

CHEMCAD System Requirements

Processor: 1 GHz or faster, 32- or 64-bit

Operating system: Windows 7 or later

(all 32- and 64-bit versions)

RAM: 1 GB for 32-bit, or 2 GB for 64-bit

Video card: DirectX 9 graphics device with

WDDM 1.0 or higher driver

Display resolution: 1920 x 1080 or higher

Hard disk space: 16 GB (32-bit) or 20 GB (64-

bit) for installation, 1 GB free space

recommended

Productivity software: Some features require

Mi ft Offi ®

Getting Started with CHEMCAD

8 CHEMCAD User Guide

on a different computer. In either case, the download process requires that you log

into Chemstations’ User Support Center.

Creating a User Support Center Account

The first time you visit Chemstations’ User Support Center, you’ll need to set up a

user account. Follow the steps below to do this.

1. On the Chemstations website home page (www.chemstations.com), click the

User Login button in the upper right area of the screen.

2. On the login screen, click the Forgot your password? button.

Figure 2-01: Clicking the Forgot your password? button on the login screen

3. On the next screen, enter a valid e-mail address, and click the Send button. Be

sure to use your company address, as the login system will match your address

against our customer database.

4. If your address is found, you will receive an e-mail from CHEMCAD Technical

Support, offering a link to reset your password. Follow the instructions in the e-

mail and at the password reset screen to complete your registration.

Note: In the event you do not receive a password reset e-mail within 24 hours, your

address may not have been found in our database. Please contact Chemstations

Technical Support ([email protected]) for assistance.

Getting Started with CHEMCAD

CHEMCAD User Guide 9

Downloading the Software

Once your user login is established, you can download the latest version of

CHEMCAD from the Chemstations website (www.chemstations.com).

On the home page, click the User Login button. The next screen will invite you to

sign in. When you have done this, click the Downloads link at the top of the screen.

The resulting Downloads list will include the .exe version of the latest

CHEMCAD installation file. When you have downloaded this file to your local

system, you can begin installation.

Installing the software

Locate the installation file, called CHEMCAD_version number_Setup.exe, and

double-click it to start the installation. The first InstallShield Wizard screen appears.

Figure 2-02: The CHEMCAD NXT - InstallShield Wizard screen

Click Next to begin the installation process. The License Agreement screen

appears, listing the terms of the CHEMCAD standard license. Once you’ve read and

understood the license terms, you’ll need to click the I accept the terms in the license

agreement button before you can click Next to proceed. Note that you have the option

to print a copy of the license agreement from this screen.

Figure 2-03: The License Agreement screen

Getting Started with CHEMCAD

10 CHEMCAD User Guide

The Destination Folder screen appears next, displaying the name of the folder

into which the CHEMCAD files will be installed by default. Normally, this

destination is C:\Program Files\Chemstations\CHEMCAD (or some variation, based

on your version of Windows), and it is recommended that you use this location

unless you have a specific need to install the program elsewhere. Click the Change

button if you want to change the file destination, or click Next to accept the

suggested destination and proceed.

Figure 2-04: The Destination Folder screen

The Setup Type screen now appears, offering a choice between complete and

custom installation. Each type of installation is described on the screen. Either accept

the default setting of Complete or click Custom to select specific components to

install, then click Next to proceed.

Figure 2-05: The Setup Type screen

This brings you to the Ready to Install the Program screen. Note that on this

screen, and in fact on any screen in the installation process, you can click Back to

return to a previous screen and verify or change your installation options. If you are

satisfied with your settings as they are, click Install to start the installation.

Getting Started with CHEMCAD

CHEMCAD User Guide 11

Figure 2-06: The Ready to Install the Program screen

The Installing CHEMCAD Suite screen appears, showing the progress of your

installation with a green status bar.

Figure 2-07: Status bar showing the progress of CHEMCAD installation

During installation, you may notice a second, smaller installation window that

pops up. This shows the progress of various software components that are being

found and installed so that CHEMCAD installation may proceed. To ensure

successful completion of the install procedure, be sure to leave this window open; it

will close automatically when all components are in place.

Figure 2-08: Software component installation message

When installation is complete, you’ll see one final screen, which states that the

InstallShield Wizard has completed installation of the CHEMCAD Suite. Click

Finish to close the installer window.

Getting Started with CHEMCAD

12 CHEMCAD User Guide

Figure 2-09: The InstallShield Wizard Completed screen

Licensing CHEMCAD

Before you can use CHEMCAD, you’ll need to set up a licensing scheme of some

type. Depending on your particular licensing agreement, you will use one of several

types of licenses to run CHEMCAD.

Types of CHEMCAD Licenses

The various types of CHEMCAD licenses are designed to fit different users’

software, hardware, and networking needs. Most licenses require the use of a

hardware device, commonly known as a dongle, to run the program.

The dongle simply plugs into a USB port on the computer, and must be plugged

in any time the program runs. If you work on a network with other CHEMCAD

users, your license may rely on a dongle plugged into a network server elsewhere in

your organization, rather than one plugged directly into your computer.

You or your organization may use one of the following types of dongles:

• SuperPro single-user dongle

• SuperProNet dongle for network use

In some instances, software licensing is provided without the use of a hardware

device:

• RMS License Manager software, which runs over a local- or wide-access

network

• System Authorization, a method that authorizes a single-user machine for

a limited time (used for software evaluation)

License Settings

To run CHEMCAD for the first time, make sure that your dongle (if applicable) is

plugged in properly, and then start the program. From the Windows Start menu,

select All Programs > Chemstations > CHEMCAD NXT.

Getting Started with CHEMCAD

CHEMCAD User Guide 13

Note: A Standard License screen appears only the first time that you run

CHEMCAD after installation. After you have reviewed the license agreement, click

Yes to continue.

The program opens, displaying a CHEMCAD splash screen. After a short time,

this screen is replaced by the CHEMCAD License Monitor dialog box, which

displays information about the license(s) that your computer is using to run

CHEMCAD.

Figure 2-10: The CHEMCAD License Monitor, displaying licenses from a local hardware dongle

Note: In some cases, this dialog may initially display with the title Searching for

Licenses, indicating that CHEMCAD has not yet detected a valid license. If your

computer is experiencing slow communication with the license server system,

CHEMCAD may simply need more time to detect the license(s). As soon as any

valid license is found, the CHEMCAD License Monitor title will appear and licensing

will proceed.

Normally, this dialog box remains in view for only a few seconds, listing all

product licenses that CHEMCAD has obtained. During that time, you can click

anywhere in the dialog box to keep it open. If you do not click in the dialog box, it

disappears from view, but you can bring it back up at any time by clicking the File

tab and then selecting Licensing.

While the CHEMCAD License Monitor dialog box is open, you can view the

various CHEMCAD licenses detected for your system and see what method (and

where applicable, which server) is being used to obtain those licenses. If your

organization uses RMS License Manager or a SuperProNet hardware key, you can

also see which other users currently hold various product licenses.

For network licenses, you can right-click a server name under a particular

product and select a licensing preference (on demand, always, or never) as shown

below.

Getting Started with CHEMCAD

14 CHEMCAD User Guide

Figure 2-11: Selecting a network licensing preference

You can use the always or never setting to turn licensing for a product absolutely

on or off, respectively. The on demand setting secures a license only when you begin

to use a specific CHEMCAD feature controlled by a certain product. This setting is

ideal in most situations, as it leaves unused licenses available for other users.

To close the CHEMCAD License Monitor screen, click the Continue button, or

click the

X in the top right corner of the screen.

Updating a License

CHEMCAD dongles require re-programming on a regular basis—either once a year

or more often, depending on your licensing agreement. This is a security measure to

reduce the likelihood that your dongle will be stolen and misused.

The dongle that you use is programmed to work only through the licensed time

period, and when that time has elapsed, the dongle must be updated before you can

continue using CHEMCAD.

Updating a dongle is a relatively simple procedure. Before your license

expiration, you or your software administrator should receive an e-mail from

Chemstations, with what’s known as a configuration file included as an attachment.

You should save this file to your Windows desktop as soon as you receive it.

Note: If you’ve updated the same dongle in the past, the new configuration file

should have the exact same file name as the previous one. If, while saving the file to

your desktop, you see a Windows message about an existing file with the same

name, you should overwrite the old file (which in any case cannot be used again),

replacing it with the new one.

It’s important to ensure that your configuration file matches your dongle. The

configuration file should be a .DNG file whose name includes a four- or five-digit

code; this code must match the number stamped onto your dongle. If the numbers

Getting Started with CHEMCAD

CHEMCAD User Guide 15

don’t match, contact your software administrator or Chemstations support to resolve

the issue.

The update e-mail also specifies the date on which you’ll need to update your

dongle. Before that date arrives, follow this procedure to perform the update:

1. Start the CHEMCAD program and click the File tab. On the command list at

left, click Licensing. This brings up the CHEMCAD License Monitor dialog

box, which displays the status of all applicable CHEMCAD product licenses,

along with your dongle type and number.

Figure 2-12: The CHEMCAD License Monitor dialog box

2. Click Setup to bring up the License Setup dialog box, then click Update

dongle as shown below.

Figure 2-13: Clicking Update dongle within the License Setup dialog box

3. The dialog box now lists all licensing dongles and displays a field for

entering the full path and file name for the dongle update file. Click Browse

to navigate to the update file.

Getting Started with CHEMCAD

16 CHEMCAD User Guide

Figure 2-14: Browsing for the dongle update file

4. In the Open dialog box, navigate to the location where you saved the .DNG

configuration file. Normally, this is the Windows desktop; if you saved your

configuration file there, click Desktop to tell CHEMCAD where to look for

the file, then select the .DNG file and click Open.

5. The License Setup dialog box now displays the directory path and file name

for the selected .DNG file. Click OK to update the dongle.

Figure 2-15: Updating the dongle with the selected update file

6. CHEMCAD re-programs the dongle, and then displays a pop-up window

stating that the update is complete.

Figure 2-16: Successful re-programming of a CHEMCAD dongle

7. Click OK to close the pop-up window. If the CHEMCAD License Monitor

screen appears, click Continue to close it.

You should now be able to proceed normally in CHEMCAD.

Getting Started with CHEMCAD

CHEMCAD User Guide 17

Getting Help with CHEMCAD

If you find that you have questions that are not addressed in this User Guide, you

can turn to several resources for CHEMCAD help.

Online Help

At any time while running CHEMCAD in an active window, you can press the [F1]

key to bring up the CHEMCAD Help screen that’s most appropriate to the task you

are currently performing or the dialog box currently displayed.

In some situations, pressing [

F1] will bring up the main CHEMCAD Help

window instead of a particular help screen. From there, you can click the Contents,

Index, or Search tab in the upper left corner of the CHEMCAD Help window, and

use these tools to find the information you need.

You can also go directly to the main CHEMCAD Help window by clicking Help

in the top right corner of the program screen. Regardless of how you open

CHEMCAD Help, it always opens in a separate window that does not interfere with

the operation of the CHEMCAD program.

The Chemstations Website

To find the most recent updates of the CHEMCAD software, manuals, and various

training tools, go to www.chemstations.com. There you’ll find the following items

available for download:

• The latest release of CHEMCAD

• A list of updates implemented in the most recent release

• CHEMCAD documentation and demos

Contacting Chemstations Technical Support

If you are unable to solve a problem or find the answer to a question using this User

Guide or the other tools listed here, you can contact Chemstations’ technical support

staff for assistance.

Our technical support engineers

are available via e-mail, or by phone

Monday through Friday, 7:00 AM

through 6:00 PM Central Standard

Time.

Outside of the United States, please see www.chemstations.com for regional

contact information.

Phone: 713.978.7700

Toll-free (U.S. and Canada): 800.243.6223

FAX: 713.978.7727

E-mail: support@chemstations.com

Getting Started with CHEMCAD

18 CHEMCAD User Guide

CHEMCAD User Guide 19

Chapter 3

The CHEMCAD Interface

This chapter takes you on a tour of the CHEMCAD screen, including the tabbed

command ribbon, the main areas of the screen, and the flowsheet drawing tools. It

also shows you some ways that you can customize the screen and various features so

that they best suit your own way of working.

The CHEMCAD Window

When you launch the CHEMCAD program for the first time, you’ll see a screen with

a tabbed ribbon at the top, a large open area in the middle, and various panes, or

specialized areas, at the edges of the screen.

Figure 3-01: The full CHEMCAD program window

Window controls

Command ribbon

Explorer pane

Workspace

Palette pane

Messages pane

Status bar

Quick Access Toolbar

Ribbon tabs

The CHEMCAD Interface

20 CHEMCAD User Guide

The Command Ribbon

The commands for using CHEMCAD are arranged into a tabbed ribbon, which is

located at the top of the program window. Each tab brings up a different set of

commands, with items grouped according to topic.

When you launch the program, the Home tab is selected, showing the most

commonly used CHEMCAD commands. To access any other groups of commands

(known as command categories), simply click the corresponding tab.

Some of the tab names are commonly found in Windows programs—namely

File, Home, View, Tools—while other tabs items such as Thermophysical,

Component Database, and Sizing are more specific to chemical process simulation.

Once you click any tab, the ribbon will display a series of related commands.

To discover the use of any item on the command ribbon, simply point your

mouse cursor at the button and watch for the tooltip to appear, as shown below.

Figure 3-02: Viewing a button’s tooltip

Note that the File tab behaves differently than the other tabs. Clicking this tab

brings up a list of commands that are applied at the file or program level, including

opening, closing, or saving a simulation; printing a flowsheet or simulation notes;

and setting up licensing and various program preferences. It’s a good idea to take a

few minutes to familiarize yourself with these commands as you begin to work with

the program.

The Quick Access Toolbar

Above the command ribbon, in the top left corner of the CHEMCAD screen, you’ll

find the Quick Access Toolbar. This toolbar provides one-click access to important

and commonly used commands—New, Open, Save, Undo, Redo, and Run All—

regardless of which command ribbon is currently selected.

Like most other areas of the CHEMCAD interface, the Quick Access Toolbar can

be customized to fit your needs. Click the down arrow at the right end of the toolbar

to access the customization options, which include turning off any of the default

commands or displaying the Quick Access Toolbar below the command ribbon.

Figure 3-03: The default commands on the Quick Access Toolbar

The CHEMCAD Interface

CHEMCAD User Guide 21

The Workspace

The area in the middle of the screen is known as the workspace. This is the main focus

of the CHEMCAD window, the place where you’ll build and edit flowsheets, view

charts and reports, and run and tweak process simulations.

When you first launch CHEMCAD, the workspace is empty. When you start to

build a flowsheet or open an existing simulation, the flowsheet displays in the

workspace.

The workspace uses tabs to enable you to switch between an open simulation and

any related features, such as Excel Data Maps, reports, and charts. At the bottom of

the workspace area, you’ll see one or more tabs whenever a simulation is open.

Each workspace tab includes a button marked with an

X; to close any tab, simply

click that tab’s

X button.

Figure 3-04: The bottom of the workspace area, showing several tabs and their X buttons

Note that any time you’ve closed a simulation and haven’t yet opened another

file, the workspace displays as an empty space.

The Explorer Pane

Along the left edge of the CHEMCAD window, you’ll see an area with a title bar at

the top that reads Explorer. At the bottom of the Explorer pane are three tabs called

Recent Files, Simulation, and Visual Basic. To view the contents of a tab, simply

click the tab name.

Figure 3-05: Explorer pane tabs

The Explorer pane tabs are presented in a tree format, with items organized into a

multi-level hierarchy. The default view shows only top-level items, but you can

expand each item to view second-level items, third-level items, and so forth.

At the left of each top-level item is a small triangle that points to the right. To

expand an item, click the triangle. Two things happen simultaneously when you

click: the tree expands to show that item’s contents, and the triangle shifts to point

downward. You can hide (or collapse) the lower-level items again by clicking the

triangle again. Figure 3-06 shows an example of an Explorer item in collapsed and

expanded view.

The CHEMCAD Interface

22 CHEMCAD User Guide

Figure 3-06: Clicking to expand an item (left); the resulting view (right)

Expanding and collapsing items in the Explorer tabs is one way that you can

make the best use of your screen space when working in CHEMCAD.

The Recent Files Tab

The Recent Files tab is selected by default when you first launch CHEMCAD. This

tab lists all the simulation files that you have opened lately, starting with the most

recent. When you first install CHEMCAD, the list is empty, but with every

simulation that you open—new files or existing ones such as built-in examples—the

list will grow, providing convenient access to files that you use frequently.

To open a simulation from the Recent Files list, simply double-click the file name

in the list.

The Simulation Tab

The Simulation tab displays by default any time a simulation is open. It provides a

series of shortcuts to common commands and settings, including:

• Components: Includes one-click access to component, electrolyte, and solids

selection

• Thermodynamics: Provides quick access to thermodynamic settings and

transport properties

• Flowsheet: Allows quick editing of UnitOp and stream data

• Sensitivity Analyses: Provides a convenient way to create, edit, and run

sensitivity analyses

• Data Maps: Enables you to create or set execution rules for a Data Map

without using the menu

• Saved Charts: Provides quick access to previously saved charts for this

simulation

The CHEMCAD Interface

CHEMCAD User Guide 23

• Groups: Provides an easy way to categorize UnitOps, streams, and

components

• Templates: Stores and organizes stream and UnitOp specifications that you

can “clone” for re-use

Expand any of these items to see and use specific features, which are described in

further detail in the appropriate chapters of this user guide.

The Visual Basic Tab

If you use Visual Basic to customize CHEMCAD, this tab provides quick and easy

access to your Visual Basic code. You can expand the Reactions, Properties, or

UnitOps item to view available subroutines for that category. Clicking the name of a

subroutine opens a Visual Basic editor in a separate window.

The Palette Pane

Along the right side of the CHEMCAD window is a pane titled Palette, which is a

repository for the various unit operation icons needed to create flowsheets. This

pane is highly customizable, so you can arrange the icons to best suit the way you

work.

By default, the Palette pane displays the All UnitOps palette. As the name

suggests, this palette shows all available UnitOps, listed in alphabetical order.

Below this palette, you’ll see other palette titles such as Heat Exchangers and

Piping and Flow. Each of these palettes includes a subset of the available UnitOp

types, focusing on one general type of equipment.

To change what you see in the Palette pane, you can do any or all of the

following:

• Select a different palette

• Change the color scheme of a palette

• Change the order of UnitOp symbols on a palette

• Remove unwanted UnitOp symbols from a palette

• Reset all palettes to default configuration

Selecting a Palette

To select a palette, simply click its title bar. The selected palette expands in place, as

shown in Figure 3-07.

The CHEMCAD Interface

24 CHEMCAD User Guide

Figure 3-07: The expanded Reactors palette

Changing the Color Scheme of a Palette

CHEMCAD offers three built-in color schemes for UnitOp symbols: Grayscale,

System Color, and Wireframe. Both the System Color and Grayscale color schemes

use color shading to give symbols a three-dimensional appearance. The Wireframe

color scheme uses no shading, for a more PFD-ready appearance.

Examples of each color scheme are shown in Figure 3-08.

Figure 3-08: A Tower Plus icon in (left to right) Grayscale, System Color, and Wireframe color

schemes

You can apply a color scheme to any UnitOp palette, to determine the

appearance of any new UnitOps you add from that palette to a flowsheet.

Before you apply a color scheme to a palette, first ensure that the desired palette

is open. Then click the current color scheme name, which is displayed next to the

palette name; this will cause a selection list to drop down. Simply click a color

scheme name to switch to that scheme.

Once you have applied a color scheme to a palette, the icons you drag from that

palette onto the flowsheet will look just like the examples on the palette. Changing

the color scheme of a palette does not affect any icons previously added to the

flowsheet from that palette.

The CHEMCAD Interface

CHEMCAD User Guide 25

Changing the Order of UnitOp Icons in a Palette

If you prefer to see UnitOp symbols in a different order than they appear on a

palette, you can rearrange them.

Note: Before you attempt to rearrange symbols on a palette, make sure that the Lock

Palette feature is turned off. Normally, this setting protects you from unintentionally

moving symbols around when you are placing items onto a flowsheet.

To turn the feature on or off, right-click any palette’s title bar and look for the Lock

Palette menu item. A check mark indicates that the feature is turned on; simply click

to clear the check mark and unlock all palettes. It’s a good idea to return palettes to a

locked state when you are not actively editing them.

To move a UnitOp symbol to a new location on the palette, click and drag the

symbol. Release the mouse button when the symbol is situated where you want it.

Other symbols on the palette will shift their positions to make room for the newly

placed item.

Removing UnitOp Symbols from a Palette

If you have identified some equipment types that you never use, you can remove

those UnitOp symbols from your palette. This can save time spent searching through

the list of UnitOps for the item you want.

To remove a symbol, first make sure that the Lock Palette feature is turned off.

Then hold down [CTRL] and right-click the UnitOp symbol you want to remove.

Select Delete from the resulting menu, then confirm the deletion by clicking Yes. The

symbol will disappear from the open palette.

Resetting All Built-in Palettes to Default Configuration

If at any time you want to return all of the built-in UnitOp palettes to their default

settings—with their original contents and the Grayscale color scheme—you can do

so with a single command. Simply right-click any palette heading and select Reset

All Palettes.

The Messages Pane

The Messages pane is located at the bottom edge of the CHEMCAD workspace. At

the bottom of this pane are three tabs: Errors and Warnings, Notifications, and

Notes.

The Errors and Warnings Tab

This tab displays a running list of error and warning messages that have been

generated while the current simulation file has been open. The oldest messages

display at the top of the list. When there are too many cumulative messages to

display in the pane, the most recent messages display and the older messages scroll

The CHEMCAD Interface

26 CHEMCAD User Guide

off the top edge of the pane. If needed, you can use the vertical scroll bar on the right

side of the pane to scroll up and review earlier messages.

To clear all messages from this tab, right-click anywhere within the tab and click

Refresh Errors and Warnings.

The Notifications Tab

This tab displays diagnostic messages from each UnitOp every time a simulation is

run. This information is helpful in troubleshooting a simulation that is not working

properly.

The text on the Notifications tab is not saved with the simulation. The text

refreshes with each run and clears when you close the simulation.

The Notes Tab

This tab provides a handy place to store additional information, in text form, about

the simulation. You can use it to list any details about the simulation, such as its

origin and any assumptions that are being made.

Any notes that you add or change are saved as part of the simulation. To delete

text from a note, simply click and drag to select the text and then press [

DELETE] on

your keyboard.

Other CHEMCAD Window Commands

The upper right corner of the CHEMCAD window has the usual Minimize,

Restore/Maximize, and Close buttons for the main program window. Beneath those

commands is an identical set of commands that control the open simulation window.

To the left of the window commands are three other items:

• Minimize the Ribbon: To minimize the command ribbon, click the caret

symbol (just to the left of Style). When the ribbon is minimized, only the

ribbon tabs are visible, and you must click a tab to see the corresponding

commands. Alternatively, you can press [

CTRL] + [F1] to toggle the full ribbon

on or off.

• Modify Visual Style: To change the color scheme of the CHEMCAD

interface, click the Style drop-down and make a selection.

• Help (F1): Click Help to open the CHEMCAD Help and Reference file.

Customizing the CHEMCAD Screen

When you first install CHEMCAD, the screen is laid out with the command ribbon at

the top, the Explorer pane on the left, the Palette pane on the right, and the Messages

pane below the workspace.

If having all of these items visible leaves you less workspace than you would

prefer, or if the location of one or more panes is less than optimal for the way that

you work, you can hide or move panes to customize your CHEMCAD screen.

The CHEMCAD Interface

CHEMCAD User Guide 27

Viewing and Hiding Screen Elements

You can view or hide the various panes and other screen elements to make optimal

use of your screen space.

To toggle a pane on or off, click the View tab and then choose Explorer, Palette,

or Messages in the Show group. Items that are currently displayed have a

background color that differs from the ribbon’s background. The Status Bar item

controls the visibility of the status bar at the bottom of the CHEMCAD window.

Resizing and Moving Items

In addition to determining which screen elements to display, you can customize

your CHEMCAD window to determine exactly where each of these items will

appear.

Resizing a Pane

The simplest way to alter the appearance of a pane is to resize it. You can make the

Explorer and Palette panes wider or narrower, or make the Messages pane shorter or

taller, by moving the inside edge, or wall, of the pane toward or away from the edge

of the main window.

To resize a pane, start by positioning your mouse cursor at the inside wall of the

pane—that is, the right edge of the Explorer pane, the left edge of the Palette pane, or

the top edge of the Messages pane. When the cursor is in the correct position for

resizing, the normal pointer will be replaced with a two-headed arrow as shown in

Figure 3-09.

Figure 3-09: The two-headed arrow cursor used for resizing panes

When you see the two-headed arrow, click and drag in the direction you want to

move the pane wall. A thick gray line shows a preview of the new pane size; when

you release the mouse button, the resized pane appears.

Moving a Pane

In addition to resizing, you can also move any of the panes in the CHEMCAD

window, either to a different edge of the screen or to the middle of the screen.

Initially, all the panes are docked, meaning that they are “snapped into” an edge

of the screen. When you undock a pane, you can put it in the location of your choice,

away from the screen edge.

To undock a pane, click and drag the pane’s title bar, that is, the bar at the top of

the pane that shows the pane name. Release the mouse button when the pane is in

the desired location.

The CHEMCAD Interface

28 CHEMCAD User Guide

Figure 3-10: The Explorer pane, undocked and moved onto the workspace

You can also dock a pane to a different edge of the screen. To do this, click the

pane’s title bar and begin to drag it away from its current location. A selection box

appears near the center of the workspace, showing all available docking locations.

When your mouse cursor points at any of these docking icons, the corresponding

area of the screen will be highlighted, as shown in Figure 3-xx. Release the mouse

button to dock the pane to that location.

Figure 3-11: Selecting a location for an undocked pane

Pinning and Unpinning Panes

In addition to moving and resizing the various panes, there’s another way that you

can customize your CHEMCAD screen: pinning and unpinning the Explorer and

Palette panes.

These two panes can take up a fair amount of horizontal screen space, and

making them very narrow isn’t an ideal way to work. Pinning and unpinning

provide a way to view full-width Explorer and Palette panes when you need these

tools, while also freeing up space when you aren’t using them.

The CHEMCAD Interface

CHEMCAD User Guide 29

Whenever either of these panes is docked at an edge of the screen, it is in one of

two states:

• Pinned, meaning that the pane is always visible

• Unpinned, meaning that the pane is mostly hidden from view, and appears only

on demand

By default, all CHEMCAD panes are initially pinned in place. You can choose to

unpin a pane if you prefer to have some extra space on the screen. To unpin a pane,

find the tiny pushpin icon in the pane’s title bar, next to the

X icon that enables you

to close the pane. If the pane is stationary, you’ll see that the pin is upright with its

point down.

Figure 3-12: The icon indicating a pinned, or stationary, pane

If you click the pin icon, the pane suddenly disappears from view—but it isn’t

gone. Instead, a small tab bearing the name of the palette appears at the edge of the

screen where the pane is docked. To see the pane reappear, you only have to roll

your mouse over that tab. When the pane appears, you’ll notice that the pushpin

icon is now horizontal. Use the tools on the Explorer or Palette normally; then, when

you no longer need the pane, just move the mouse pointer elsewhere. The pane will

automatically hide itself until the next time you roll the mouse over the tab.

Figure 3-13: An unpinned pane in use; note the horizontal pin icon and the Explorer tab at left

To re-pin an unpinned pane, point to the tab to make the pane appear and then

click the pin icon. The pin turns so that it is once again upright, and the pane is once

again a permanent fixture on the CHEMCAD screen.

Flowsheet Drawing Tools

Most of the commands used for drawing flowsheets are accessed via the Drawing

tab. The drawing commands are grouped by function, for easy access.

The CHEMCAD Interface

30 CHEMCAD User Guide

The Workspace Group

The Workspace group includes features that help with alignment of flowsheet

objects, behavior of stream lines, and text objects on the flowsheet.

Figure 3-14: The Drawing tab’s Workspace group

You can turn on a visible workspace grid to use as a guide while creating your

flowsheet. Click Show Grid to toggle this feature on or off.

The option called Snap to Grid can help with alignment of objects on the

flowsheet. When this option is turned on, items that you move on the workspace will

align themselves with the nearest vertical and horizontal grid lines.

The Snap to Center feature helps you to neatly line up flowsheet elements

relative to one another. When this option is turned on, items that you move around

on the workspace will show when they are centrally aligned with nearby objects, as

indicated by a blue dotted line.

Figure 3-15: The Snap to Center feature in action, showing when objects are centrally aligned

Selecting Change Grid Size brings up the Grid dialog box, which enables you to

customize the look and spacing of the grid lines when the visible grid is turned on.

The Stream Styles tool enables you to customize the way that stream lines

appear on the flowsheet. The Stream Styles dialog includes settings for stream line