Concise Eurocode 2

for Bridges

A cement and concrete industry publication

For the design of concrete bridges to BS EN 1992-1-1 and BS EN 1992-2

and their National Annexes

O Brooker

BEng CEng MICE MIStructE

P A Jackson BSc(Hons) PhD CEng FICE FIStructE

S W Salim BEng(Hons) PhD CEng MICE

Foreword

The introduction of European standards to UK construction is a significant event as for the

first time all design and construction codes within the EU will be harmonised. The ten

design standards, known as the Eurocodes, will affect all design and construction activities as

current British Standards for structural design are due to be withdrawn in March 2010.

The cement and concrete industry recognised the need to enable UK design professionals

to use Eurocode 2, Design of concrete structures, quickly efficiently and with confidence.

Supported by government, consultants and relevant industry bodies, the Concrete Industry

Eurocode 2 Group (CIEG) was formed in 1999 and this group has provided the guidance for a

coordinated and collaborative approach to the introduction of Eurocode 2.

As a result, a range of resources is being developed and made available through The Concrete

Centre (see www.eurocode2.info). One of those resources, Concise Eurocode 2, published in

2006, is targeted at structural engineers designing concrete framed buildings. Whilst there are

many similarities in the design of buildings and bridges, there are also significant differences

and hence Eurocode 2 has a distinct part for the design of bridges. This publication is based

on the style of Concise Eurocode 2, but has been completely revised and rewritten to suit the

requirements of Eurocode 2, Part 2 and the current design practices for concrete bridge design.

Relevant extracts have been incorporated from Precast Eurocode 2: Design manual published

by British Precast, which is a similar document for designers of precast concrete. The authors

are grateful for the permission granted by British Precast.

Acknowledgements

The Concrete Centre would to thank Neil Loudon and Hideo Takano, both of the Highways

Agency, for their support and comments in producing this document. We would also like to

thank Steve Denton of Parsons Brinckerhoff, Chris Hendy of Atkins and Paul White of Halcrow

for their helpful comments. Thanks are also due to Gillian Bond, Sally Huish and the design

team at Michael Burbridge Ltd for their work on the production.

The copyright of British Standards extracts reproduced in this document is held by the British

Standards Institution (BSI). Extracts have been reproduced with BSI’s permission under the

terms of Licence No: 2009RM0003. No other use of this material is permitted. This publication

is not intended to be a replacement for the standard and may not reflect the most up-to-date

status of the standard. British Standards can be obtained in PDF or hard copy formats from

the BSI online shop: www.bsigroup.com/Shop or by contacting BSI Customer Services for hard

copies only: Tel:+44 (0)20 8996 9001, Email: [email protected].

Published by The Concrete Centre, part of the Mineral Products Association

Riverside House, 4 Meadows Business Park, Station Approach, Blackwater, Camberley, Surrey GU17 9AB

Tel: +44 (0)1276 606800 Fax: +44 (0)1276 606801 www.concretecentre.com

Cement and Concrete Industry Publications (CCIP) are produced through an industry initiative

to publish technical guidance in support of concrete design and construction.

CCIP publications are available from the Concrete Bookshop at www.concretebookshop.com

Tel: +44 (0)7004 607777

CCIP-038

Published July 2009

ISBN 978-1-904818-82-3

Price Group P

© MPA – The Concrete Centre

All advice or information from MPA - The Concrete Centre is intended only for use in the UK by those who will evaluate

the significance and limitations of its contents and take responsibility for its use and application. No liability (including that

for negligence) for any loss resulting from such advice or information is accepted by Mineral Products Association or its

subcontractors, suppliers or advisors. Readers should note that the publications from MPA - The Concrete Centre are subject to

revision from time to time and should therefore ensure that they are in possession of the latest version.

Printed by Michael Burbridge Ltd, Maidenhead, UK.

i

Symbols iv

1 Introduction 1

1.1 Scope 2

2 Basis of design 3

2.1 General 3

2.2 Basicrequirements 3

2.3 Limitstatedesign 4

2.4 Assumptions 9

2.5 Foundationdesign 10

3 Materials 11

3.1 Concrete 11

3.2 Steelreinforcement 13

3.3 Prestressingsteel 14

4 Durability and cover 17

4.1 General 17

4.2 Coverforbond,c

min,b

18

4.3 Coverfordurability,c

min,dur

18

4.4 Chemicalattack 22

4.5

Dc

dev

andotherallowances 23

5 Structural analysis 25

5.1 General 25

5.2 Idealisationofthestructure 25

5.3 Methodsofanalysis 27

5.4 Loading 29

5.5 Geometricalimperfections 29

5.6 Designmomentsincolumns 31

5.7 Corbels 36

5.8 Lateralinstabilityofslenderbeams 38

6 Bending and axial force 39

6.1 Assumptions 39

7 Shear 41

7.1 General 41

7.2 Resistanceofmembersnotrequiringshearreinforcement 41

7.3 Resistanceofmembersrequiringshearreinforcement 44

Contents

ConciseEurocode2forBridges

ii

8 Punching shear 50

8.1 General 50

8.2 Appliedshearstress 50

8.3 Controlperimeters 54

8.4 Punchingshearresistancewithoutshearreinforcement 55

8.5 Punchingshearresistancewithshearreinforcement 56

8.6 Punchingshearresistanceadjacenttocolumns 56

8.7 Controlperimeterwhereshearreinforcementisnolongerrequired,u

out

56

8.8 Distributionofshearreinforcement 57

8.9 Punchingshearresistanceoffoundationbases 58

9 Torsion 59

9.1 General 59

9.2 Torsionalresistances 59

9.3 Combinedtorsionandshear 61

10 Strut-and-tie models, bearing zones and partially loaded areas 62

10.1 Designwithstrut-and-tiemodels 62

10.2 Partiallyloadedareas 65

10.3 Bearingzonesofbridges 66

11 Prestressed members and structures 67

11.1 General 67

11.2 BrittleFracture 67

11.3 Prestressingforceduringtensioning 69

12 Fatigue 72

12.1 Verificationconditions 72

12.2 Internalforcesandstressesforfatigueverification 72

12.3 Verificationofconcreteundercompressionorshear 73

12.4 Limitingstressrangeforreinforcementundertension 74

13 Serviceability 76

13.1 General 76

13.2 StressLimitation 76

13.3 Calculationofcrackwidths 76

13.4 Controlofcracking 79

13.5 Minimumreinforcementareasofmainbars 80

13.6 Controlofdeflection 83

14 Detailing – general requirements 85

14.1 General 85

14.2 Spacingofbars 85

14.3 Mandrelsizesforbentbars 85

14.4 Anchorageofbars 86

14.5 Ultimatebondstress 88

14.6 AnchorageoftendonsatULS 89

14.7 Anchorageoftendonsattransferofprestress 90

14.8 Laps 90

iii

15 Detailing – particular requirements 94

15.1 General 94

15.2 Beams 94

15.3 One-wayandtwo-wayspanningslabs 98

15.4 Flatslabs 98

15.5 Columns 100

15.6 Walls 101

15.7 Pilecaps 102

15.8 Boredpiles 103

15.9 Requirementsforvoidedslabs 103

15.10 Prestressing 104

15.11 Connections 105

15.12 Bearings 106

16 Design for the execution stages 109

17 Design aids 110

17.1 Designforbending 110

17.2 Designforbeamshear 112

17.3 Designforpunchingshear 114

17.4 Designforaxialloadandbending 115

18 References 122

iv

Symbols and abbreviations used in this publication

Symbol Definition

IxI Absolutevalueofx

1/ Curvatureataparticularsection

Cross-sectionalarea;Accidentalaction

Variablesusedinthedeterminationofl

lim

c

Cross-sectionalareaofconcrete

c,eff

Effectiveareaofconcreteintension

ct

Areaofconcreteinthatpartofthesectionthatiscalculatedtobeintensionjustbefore

theformationofthefirstcrack

d

Designvalueofanaccidentalaction

k

Areaenclosedbythecentrelinesofconnectingwallsincludingtheinnerhollowarea

(torsion)

p

Areaofprestressingtendonortendons

p

'

Areaofprestressingtendonswithin

c,eff

s

Cross-sectionalareaofreinforcement

s,min

Minimumcross-sectionalareaofreinforcement

s,prov

Areaofsteelprovided

s,req

Areaofsteelrequired

s1

Areaofreinforcingsteelinlayer1

s2

Areaofcompressionsteel(inlayer2)

sl

Areaofthetensilereinforcementextendingatleast

bd

+beyondthesectionconsidered

sM

(

sN

) Totalareaofreinforcementrequiredinsymmetrical,rectangularcolumnstoresistmoment

(axialload)usingsimplifiedcalculationmethod

st

Cross-sectionalareaoftransversesteel(atlaps)

sw

Cross-sectionalareaofshearreinforcement

sw

Areaofpunchingshearreinforcementinoneperimeteraroundthecolumn

sw,min

Minimumcross-sectionalareaofshearreinforcement

sw,min

Minimumareaofpunchingshearreinforcementinoneperimeteraroundthecolumn

Distance,allowanceatsupports

Geometricdata

D Deviationforgeometricaldata

Anexponent(inconsideringbiaxialbendingofcolumns)

Projectionofthefootingfromthefaceofthecolumnorwall

b

Halfthecentre-to-centrespacingofbars(perpendiculartotheplaneofthebend)

l

Distancebywhichthelocationwhereabarisnolongerrequiredforbendingmomentis

displacedtoallowfortheforcesfromthetrussmodelforshear.(‘Shift’distanceforcurtailment)

v

Distancebetweenbearingsorfaceofsupportandfaceofload

1

,

1

Dimensionsofthecontrolperimeteraroundanelongatedsupport(punchingshear)

Overallwidthofacross-section,orflangewidthinaT-orL-beam

0

Widthofthebottomflangeofthesection

e

Effectivewidthofaflatslab(adjacenttoperimetercolumn)

eff

Effectivewidthofaflange

eq

(

eq

) Equivalentwidth(height)ofcolumn=()forrectangularsections

min

MinimumwidthofwebonT-,I-orL-beams

t

Meanwidthofthetensionzone.ForaT-beamwiththeflangeincompression,onlythe

widthofthewebistakenintoaccount

v

Symbol Definition

w

WidthofthewebonT-,I-orL-beams.Minimumwidthbetweentensionandcompression

chords

y

,

z

Dimensionsofthecontrolperimeter(punchingshear)

D Permitteddeviationfrom

nom

(BSEN13760)

D

,dev

Allowancemadeindesignfordeviation

min

Minimumcover(duetotherequirementsforbond,

min,b

ordurability

min,dur

)

nom

Nominalcover(minimumcoverplusallowancefordeviations)

y

,

x

Columndimensionsinplan

1

,

2

Dimensionsofarectangularcolumn.Foredgecolumns,

1

ismeasuredperpendicularto

thefreeedge(punchingshear)

Diameterofacircularcolumn;Diameterofmandrel;Diameter

Ed

Fatiguedamagefactor

Effectivedepthtotensionsteel

2

Effectivedepthtocompressionsteel

c

Effectivedepthofconcreteincompression

eff

Effectivedepthoftheslabtakenastheaverageoftheeffectivedepthsintwoorthogonal

directions(punchingshear)

g

Largestmaximumaggregatesize

Ashortlengthofaperimeter(punchingshear)

Effectofaction;Elasticmodulus

c

,

c(t)

Tangentmodulusofelasticityofnormalweightconcreteatastressofs

c

=0andattime,

,days

c,eff

Effectivemodulusofelasticityofconcrete

cd

Designvalueofmodulusofelasticityofconcrete

cm

Secantmodulusofelasticityofconcrete

d

Designvalueoftheeffectofactions

Bendingstiffness

p

Designvalueofelasticityofprestressingsteel

s

Designvalueofmodulusofelasticityofreinforcingsteel

Exp. Expression

EQU Staticequilibrium

Eccentricity

2

Deflection(usedinassessing

2

inslendercolumns)

i

Eccentricityduetoimperfections

par

Eccentricityparalleltotheslabedgeresultingfromamomentaboutanaxisperpendicular

totheslabedge(punchingshear)

y

,

z

Eccentricity,

Ed

/

Ed

alongyandzaxesrespectively(punchingshear)

Action

bt

Tensileforceinthebaratthestartofthebendcausedbyultimateloads

c

(

s

) Forceinconcrete(steel)

cd

Designvalueoftheconcretecompressionforceinthedirectionofthelongitudinal

memberaxis

cr

Absolutevalueofthetensileforcewithintheflangeimmediatelypriortocrackingdueto

thecrackingmomentcalculatedwith

ct,eff

d

Designvalueofanaction

E

Tensileforceinreinforcementtobeanchored

Ed

Compressiveforce,designvalueofsupportreaction

k

Characteristicvalueofanaction

Symbols and abbreviations used in this publication

vi

Symbol Definition

rep

Representativeaction(=c

k

wherec=factortoconvertcharacteristictorepresentative

action)

Rs

Resistingtensileforceinsteel

s

Tensileforceinthebar

td

Designvalueofthetensileforceinlongitudinalreinforcement

D

td

Additionaltensileforceinlongitudinalreinforcementduetothetrussshearmodel

wd

Designshearstrengthofweld,designvalueoftheforceinstirrupsincorbels

Wk

Characteristicvalueofwindforce(AnnexA2,BSEN1990)

Frequency

bd

Ultimatebondstress

c

Compressivestrengthofconcrete

cd

Designvalueofconcretecompressivestrength

cd,fat

Designfatiguestrengthofconcrete

cd,pl

Designcompressivestrengthofplainconcrete

ck

Characteristiccompressivecylinderstrengthofconcreteat28days

ck

(

0

) Characteristicconcretecompressivestrengthattimeofloading

ck,cube

Characteristiccompressivecubestrengthofconcreteat28days

cm

Meanvalueofconcretecylindercompressivestrength

ct,d

Designtensilestrengthofconcrete(a

ct

ct,k

/g

C

)

ct,eff

Meantensilestrengthofconcreteeffectiveatthetimecracksmaybefirstexpectedto

occur.

ct,eff

=

ctm

attheappropriateage

ct,k

Characteristicaxialtensilestrengthofconcrete

ctb

Tensilestrengthpriortocrackinginbiaxialstateofstress

ctm

Meanvalueofaxialtensilestrengthofconcrete

ctx

Appropriatetensilestrengthforevaluationofcrackingbendingmoment

ctk,0.05

5%fractilevalueofaxialtensilestrengthofconcrete

ctk,0.95

95%fractilevalueofaxialtensilestrengthofconcrete

cvd

Concretedesignstrengthinshearandcompression(plainconcrete)

p

Tensilestrengthofprestressingsteel

p0.1

0.1%proof-stressofprestressingsteel

p0.1k

Characteristic0.1%proof-stressofprestressingsteel

p0.2k

Characteristic0.2%proof-stressofprestressingsteel

pk

Characteristictensilestrengthofprestressingsteel

sc

CompressivestressincompressionreinforcementatULS

t

Tensilestrengthofreinforcement

t,k

Characteristictensilestrengthofreinforcement

y

Yieldstrengthofreinforcement

yd

Designyieldstrengthoflongitudinalreinforcement,

sl

yk

Characteristicyieldstrengthofreinforcement

ywd

Designyieldstrengthoftheshearreinforcement

ywd,ef

Effectivedesignstrengthofpunchingshearreinforcement

ywk

Characteristicyieldstrengthofshearreinforcement

k

Characteristicvalueofapermanentaction

k

Characteristicvalueofapermanentactionperunitlengthorarea

i

Horizontalactionappliedatalevel

Overalldepthofacross-section;Height

vii

Symbol Definition

0

Notionalsizeofcross-section

f

Depthoffooting;Thicknessofflange

H

Verticalheightofadroporcolumnheadbelowsoffitofaslab(punchingshear)

s

Depthofslab

Secondmomentofareaofconcretesection

Radiusofgyration

Creepfunction

Ed

/

2

ck

.Ameasureoftherelativecompressivestressinamemberinflexure

Factortoaccountforstructuralsystem(deflection)

Valueofabovewhichcompressionreinforcementisrequired

c

Factorforcrackingandcreepeffects

r

Correctionfactorforcurvaturedependingonaxialload

s

Factorforreinforcementcontribution

h Factorfortakingaccountofcreep

Coefficientorfactor

Unintentionalangulardisplacementforinternaltendons

c

Coefficientallowingforthenatureofthestressdistributionwithinthesectionimmediately

priortocrackingandforthechangeoftheleverarmasaresultofcracking(minimumareas)

t

Factorincrackwidthcalculationswhichdependsonthedurationofloading

Clearheightofcolumnbetweenendrestraints

Heightofthestructureinmetres

(or) Length;Span

0

Effectivelength(ofcolumns)

0

Distancebetweenpointsofzeromoment

0

Designlaplength

bd

Designanchoragelength

b,eq

Equivalentanchoragelength

b,min

Minimumanchoragelength

b,rqd

Basicanchoragelength

eff

Effectivespan

H

Horizontaldistancefromcolumnfacetoedgeofadroporcolumnheadbelowsoffitofa

slab(punchingshear)

n

Cleardistancebetweenthefacesofsupports

s

Floortoceilingheight

x

,

y

Spansofatwo-wayslabinthexandydirections

Bendingmoment.Momentfromfirstorderanalysis

Momentresistanceofasinglyreinforcedsection(abovewhichcompressionreinforcement

isrequired)

0,Eqp

Firstorderbendingmomentinquasi-permanentloadcombination(SLS)

01

,

02

FirstorderendmomentsatULSallowancesforimperfections

0Ed

Equivalentfirstordermomentincludingtheeffectofimperfections(ataboutmidheight)

2

Nominalsecondordermomentinslendercolumns

Ed

Designvalueoftheappliedinternalbendingmoment

Edy

,

Edz

Designmomentintherespectivedirection

freq

Appliedbendingmomentduetofrequentcombination

Rdy

,

Rdz

Momentresistanceintherespectivedirection

viii

Symbol Definition

Rd,max

Maximumtransversemomentresistance

rep

Crackingbendingmoment

Numberofverticalmemberscontributingtoaneffect

Mass;Slabcomponents

Axialforce

NA NationalAnnex

a

,

b

Longitudinalforcescontributingto

i

Ed

Designvalueofaxialforce(tensionorcompression)atULS

NDP NationallyDeterminedParameter(s)aspublishedinacountry’sNationalAnnex

AxialstressatULS

Ultimateaction(load)perunitlength(orarea)

Platecomponents

Numberofbars

b

Numberofbarsinthebundle

Prestressingforce

0

Initialforceattheactiveendofthetendonimmediatelyafterstressing

c

Characteristicconstructionload

fat

Characteristicfatigueload

k

Characteristicvalueofavariableaction

k1

(

ki

) Characteristicvalueofaleadingvariableaction(Characteristicvalueofanaccompanying

variableaction)

Sn,k

Characteristicvalueofsnowload

k

Characteristicvalueofavariableactionperunitlengthorarea

ud

Maximumvalueofcombinationreachedinnon-linearanalysis

Resistance

Verticalbearingresistanceperunitarea(foundations)

d

Designvalueoftheresistancetoanaction

Relativehumidity

Radius;Correctingfactorforprestress

cont

Thedistancefromthecentroidofacolumntothecontrolsectionoutsidethecolumnhead

inf,

sup

Allowanceinserviceabilityandfatiguecalculationsforpossiblevariationsinprestress

m

RatiooffirstorderendmomentsincolumnsatULS

Internalforcesandmoments;Firstmomentofarea

S,N,R Cementtypes

SLS Serviceabilitylimitstate(s)–correspondingtoconditionsbeyondwhichspecifiedservice

requirementsarenolongermet

Spacingofthestirrups;Spacingbetweencracks

r

Radialspacingofperimetersofshearreinforcement

r,max

Maximumfinalcrackspacing

t

Tangentialspacingshearreinforcementalongperimetersofshearreinforcement

Torsionalmoment;Tensileforce

Ed

Designvalueoftheappliedtorsionalmoment

k

Characteristicvalueofthermalactions

Rd

Designtorsionalresistancemoment

Rd,max

Maximumdesigntorsionalresistancemomentresistance

Thickness;Timebeingconsidered;Breadthofsupport;Timeaftertensioning

ix

Symbol Definition

0

Theageofconcreteatthetimeofloading

0,T

Temperatureadjustedageofconcreteatloadingindays

ef,i

Effectivewallthickness(torsion)

inf

Thicknessofthebottomflangeofthesection

ULS Ultimatelimitstate(s)–associatedwithcollapseorotherformsofstructuralfailure

Perimeterofconcretecross-section,havingarea

c

Perimeterofthatpartwhichisexposedtodrying

Circumferenceofouteredgeofeffectivecross-section(torsion)

Componentofthedisplacementofapoint

0

Perimeteradjacenttocolumns(punchingshear)

1

Basiccontrolperimeter,(at2fromfaceofload)(punchingshear)

1*

Reducedcontrolperimeteratperimetercolumns(at2fromfaceofload)(punchingshear)

i

Lengthofthecontrolperimeterunderconsideration(punchingshear)

k

Perimeterofthearea

k

(torsion)

out

Perimeteratwhichshearreinforcementisnolongerrequired

Shearforce

Ed

Designvalueoftheappliedshearforce

Ed,red

Appliedshearforcereducedbytheforceduetosoilpressurelessselfweightofbase

(punchingshear,foundations)

Rd,c

Shearresistanceofamemberwithoutshearreinforcement

Rd,max

Shearresistanceofamemberlimitedbythecrushingofcompressionstruts

Rd,s

Shearresistanceofamembergovernedbytheyieldingofshearreinforcement

Transverseshearorcomponentofthedisplacementofapoint

Ed

Punchingshearstress

Ed

Shearstressforsectionsshearreinforcement(=

Ed

/

w

)

Ed,z

Shearstressforsectionsshearreinforcement(=

Ed

/

w

=

Ed

/

w

0.9)

Rd,c

Designshearresistanceofconcretewithoutshearreinforcementexpressedasastress

Rd,cs

Designpunchingshearresistanceofconcreteshearreinforcementexpressedasa

stress(punchingshear)

Rd,max

Resistanceofconcretestrutsexpressedasastress

1

Factorcorrespondingtoadistributionofshear(punchingshear)

Componentofthedisplacementofapoint

k

Crackwidth

max

Limitingcalculatedcrackwidth

Advisorylimitofpercentageofcoupledtendonsatasection

X0,XA,XC, Concreteexposureclasses

XD,XF,XS

Neutralaxisdepth

Distanceofthesectionbeingconsideredfromthecentrelineofthesupport

Co-ordinates;Planesunderconsideration

c

Depthofthecompressionzone

u

Depthoftheneutralaxisattheultimatelimitstateafterredistribution

Leverarmofinternalforces

cp

Distancebetweencentreofgravityofconcretesectionandtendons

s

Leverarmforprestress

a Angle;Angleofshearlinkstothelongitudinalaxis;Ratio

a Longtermeffectscoefficient

x

Symbol Definition

a Ratiobetweenprincipalstresses

a Deformationparameter

a

1

,a

2

,a

3

Factorsdealingwithanchorageandlapsofbars

a

4

,a

5

,a

6

a

1

,a

2

,a

3

Factorsusedincreepcalculations

a

cc

(a

ct

) Acoefficienttakingintoaccountlongtermeffectsofcompressive(tensile)loadandthe

wayloadisapplied

a

cw

Coefficienttakingaccountofthestateofstressinthecompressionchord

a

e

Effectivemodularratio

a

h

Reductionfactorfory

b Angle;Ratio;Coefficient

b Factordealingwitheccentricity(punchingshear)

b(

cm

) Factortoallowfortheeffectofconcretestrengthonthenotionalcreepcoefficient

b

H

Coefficentdependingontherelativehumidityandthenotionalmembersize

b(

0

) Factortoallowfortheeffectofconcreteageatloadingonthenotionalcreepcoefficient

b(,

0

) Coefficienttodescribethedevelopmentofcreepwithtimeafterloading

g Partialfactor

g

A

Partialfactorforaccidentalactions,

g

C

Partialfactorforconcrete

g

C,fat

Partialfactorforfatigueofconcrete

g

F

Partialfactorforactions,

g

F,fat

Partialfactorforfatigueactions

g

f

Partialfactorforactionswithouttakingaccountofmodeluncertainties

g

g

Partialfactorforpermanentactionswithouttakingaccountofmodeluncertainties

g

G

Partialfactorforpermanentactions,

g

M

Partialfactorforamaterialproperty,takingaccountofuncertaintiesinthematerial

propertyitself,ingeometricdeviationandinthedesignmodelused

g

P

Partialfactorforactionsassociatedwithprestressing,

g

Q

Partialfactorforvariableactions,

g

S

Partialfactorforreinforcingsteelorprestressingsteel

g

S,fat

Partialfactorforreinforcingorprestressingsteelunderfatigueloading

g

SH

Partialfactorforshrinkage

d Ratiooftheredistributedmomenttotheelasticbendingmoment.

e

c

Compressivestraininconcrete

e

c1

Compressivestrainintheconcreteatthepeakstress

c

e

c2

Compressivestrainlimitinconcreteforconcreteinpureaxialcompressionorstrainin

concreteatreachingmaximumstrengthassuminguseoftheparabolic-rectangular

relationship

e

c3

Compressivestrainlimitinconcreteforconcreteinpureaxialcompressionorstrainin

concreteatreachingmaximumstrengthassuminguseofthebilinearstress-strain

relationship

e

ca

Autogenousshrinkagestrain

e

cc

Creepstrain

e

cd

Dryingshrinkagestrain

e

cm

Meanstraininconcretebetweencracks

e

cs

Totalshrinkagestrain

e

cu

Ultimatecompressivestrainintheconcrete

e

cu2

Ultimatecompressivestrainlimitinconcretewhichisnotfullyinpureaxialcompression

assuminguseoftheparabolic-rectangularstress-strainrelationship(numericallye

cu2

=e

cu3

)

xi

Symbol Definition

e

cu3

Ultimatecompressivestrainlimitinconcretewhichisnotfullyinpureaxialcompression

assuminguseofthebilinearstress-strainrelationship

e

p(0)

Initialstraininprestressingsteel

De

p

Changeinstraininprestressingsteel

e

s

Straininreinforcingsteel

e

sm

Meanstraininreinforcement

e

u

Strainofreinforcementorprestressingsteelatmaximumload

e

ud

Designlimitforstrainforreinforcingsteelintension=

0.9e

uk

e

uk

Characteristicstrainofreinforcement(orprestressingsteel)atmaximumload

e

y

Reinforcementyieldstrain

n Factordefiningeffectivestrength(=1for≤C50/60)

n

1

Coefficientforbondconditions

n

2

Coefficientforbardiameter

n

p1

Coefficientthattakesintoaccountthetypeoftendonandthebondsituationatrelease

y

Angle;Angleofcompressionstruts(shear)

y

fat

Inclinationofcompressivestruts

y

i

Inclinationusedtorepresentimperfections

l Slendernessratio

l Damageequivalentfactorsinfatigue

l Factordefiningtheheightofthecompressionzone(=0.8for≤C50/60)

l

lim

Limitingslendernessratio(ofcolumns)

m Coefficientoffrictionbetweenthetendonsandtheirducts

m Characteristicvalueofthetensilestrengthofprestressingsteel

v Poisson'sratio

v

1

Strengthreductionfactorforconcretecrackedinshear

j Creepredistributionfunction

j Bondstrengthratio

j

1

Adjustedareaofbondstrength

r Requiredtensionreinforcementratio.Assume

s

/

r Ovendrydensityofconcreteinkg/m

3

r' Reinforcementratioforrequiredcompressionreinforcement,

s2

/

r

0

Referencereinforcementratio

ck

0.5

x10

–3

r

1

Percentageofreinforcementlappedwithin0.65

0

fromthecentrelineofthelapbeing

considered

r

1000

Valueofrelaxationloss(in%)at1000hoursaftertensioningandatameantemperatureof20°C

r

l

Reinforcementratioforlongitudinalreinforcement

r

w

Reinforcementratioforshearreinforcement

s

c

Compressivestressintheconcrete

s

cp

Compressivestressintheconcretefromaxialloadorprestressing

s

cu

Compressivestressintheconcreteattheultimatecompressivestraine

cu

s

gd

Designvalueofthegroundpressure

s

pi

Theabsolutevalueofinitialprestress

s

pm0

Theabsolutevalueofinitialprestressduringpost-tensioning

s

Rd,max

Designstrengthofconcretestrut

s

s

StressinreinforcementatSLS

s

s

Absolutevalueofthemaximumstresspermittedinthereinforcementimmediatelyafter

theformationofthecrack

xii

Symbol Definition

s

sc

(s

st

) Stressincompression(andtension)reinforcement

s

sd

Designstressinthebarattheultimatelimitstate

s

sr

Stressinthetensionreinforcementcalculatedonthebasisofacrackedsectionunderthe

loadingconditionscausingfirstcracking

t Torsionalshearstress

F DynamicfactoraccordingtoBSEN1991-2

h

0

Notionalcreepcoefficient

h(∞,

0

) Finalvalueofcreepcoefficient

h

ef

Effectivecreepfactor

h

fat

Damageequivalentimpactfactorinfatigue

h

nl

(∞,

0

) Non-linearnotionalcreepcoefficient

h

p

Equivalentdiameteroftendon

h(,

0

) Creepcoefficient,definingcreepbetweentimesand

0

,relatedtoelasticdeformationat28days

h

RH

Factortoallowfortheeffectofrelativehumidityonthenotionalcreepcoefficient

f Bardiameter;Diameterofprestressingduct

f

eq

Equivalentbardiameter

f

m

Mandreldiameter

f

n

Equivalentdiameterofabundleofreinforcingbars

X Ageingcoefficient

c Factorsdefiningrepresentativevaluesofvariableactions

c

0

Combinationvalueofavariableaction(e.g.usedwhenconsideringULS)

c

1

Frequentvalueofavariableaction(e.g.usedwhenconsideringwhethersectionwillhave

crackedornot)

c

2

Quasi-permanentvalueofavariableaction(e.g.usedwhenconsideringdeformation)

w Mechanicalreinforcementratio=

s

yd

/

c

cd

≤1

1

Introduction

1

Introduction

BSEN1992-1-1(Eurocode2:Part1-1

[

1

]

)setsoutgeneralrules

for the design of concrete structures and rules for the design of buildings. BS EN 1992-2

(Eurocode 2 -Part 2Concrete bridges- Designand detailing rules)

[

2

]

providesadditional or

amendedguidancetoPart1-1forbridgestructures.

TheaimofthisistodistilfromallrelevantpartsofBSEN1992and

theUKNationalAnnexes materialthatwillbecommonlyusedinthedesignofnormalbridge

structures. Eachcountry can publish non-contradictory,complementary information, and for

concretebridgedesign,PD6687,Part2

[

3

]

givesusefulguidance.Materialfromthisdocumentis

alsoincludedwhereappropriate,andpresentedonapaleyellowbackgroundtodistinguishit

fromthemaintext.

As far as possible, the Eurocode clauses are repeated verbatim.One ofthe objectives is to

embed the UK NationalAnnex values into the document for ease of use. Due to the way

Nationally Determined Parameters (NDPs) are introduced in the Eurocodes it has been

necessaryinsomeplacestomodifythetextforclarityofreading.Ithasnotbeentheintention

tomodifythemeaningofthetextandclearlyifthereisanydoubtastothemeaningthenthe

originalEurocodeversionshouldbeadopted.

Further,someoftheoriginaltexthasbeenmodifiedtoreduceitslength,whilekeepingthesame

meaning.Inthiscasethetexthasbeengivenagreybackgroundtodrawthereader’sattention

tothefactthatthetextisnotstrictlyfromtheCode.Likewiseothertext,derivedformulae,

tablesandillustrationsthatareprovidedtoassistthedesignersbutthatarenottakendirectly

fromtheoriginalhavebeengivenagreybackground.Asbefore,itisintendedtoconveythe

originalmeaningandwhereanydoubtexiststhemeaningofEurocode2shouldbeadopted.

TheNDPs arerecognitionthat each Member Stateof theEU isresponsible fordetermining

matters such as safety and current practice andallow individualcountries to set their own

values.Asnotedabove,theUKvalueshavebeenadoptedthroughout,buthavebeenhighlighted

withagreenbackgroundsothatitiscleartothereaderwhatNDPvaluehasbeenused.

Guide to presentation

Greyshadedtext,

tablesandfigures

ModifiedEurocode2textandadditionaltext,derivedformulae,

tablesandillustrationsnot fromEurocode2

Yellowshadedtext,

tablesandfigures

AdditionaltextfromPD6687

[6]

orPD6687-2

[3]

BS EN 1992-1-1

6.4.4

Relevantcodeandclausesorfigurenumbers

BS EN 1992-1-1

NA

FromtherelevantUKNationalAnnex

BS EN 1992-1-1

6.4.4 & NA

FrombothEurocode2-1-1andUKNationalAnnex

Section 5.2

Relevantpartsofthispublication

1.0

NationallyDeterminedParameter.UKvalueshavebeenused

throughout

For ease of reference, this guide is repeated on the inside back cover.

2

Scope

Thispublicationisintendedtocoverthedesignofatypicalbridge;thereareparticulartypesof

bridgessuchassuspensionbridgesandsegmentalbridgesthatshouldnotbedesignedwithout

referencetotheCodeitself.Itshouldalsobenotedthatnoteverymethodpresentedinthe

Codeisgivenhere.Generally,thesimplestandmoreconservativemethodshavebeenincluded

andthereforethereadermayfindtherearebenefitstobegainedbyusingothermethodsand

shouldconsulttheCodeontheseoccasions.

Thispublicationdoesnotcoverthemethodofdesigningconcreteelementsusingmembrane

rules.Membraneelementsmaybeusedforthedesignoftwo-dimensionalconcreteelements

subject to a combination of internal forces evaluated by means of a linear finite element

analysis.ThereadershouldrefertoBSEN1992-2AnnexLLinconjunctionwithAnnexFand

Cl. 6.109 for detailed guidance. For the design or verification of shell elements subject to

bendingalone (i.e.withzeromembrane forces)the approachesgiven byWoodArmer

[4]

and

Denton&Burgoyne

[5]

maygenerallybeused.

1.1

3

Basisofdesign

Basis of design

General

BSEN1992-1-1

[

1

]

andBSEN1992-2

[

2

]

shouldbeusedinconjunctionwithBSEN1990:

[

7

]

,which:

Establishesprinciplesandrequirementsforthesafety,serviceabilityanddurabilityof

structures.

Describesthebasisfortheirdesignandverification.

Givesguidelinesforrelatedaspectsofstructuralreliability.

Basic requirements

General

Astructureshouldbedesignedandexecuted(constructed)insuchawaythatitwill,duringits

intendedlife,withappropriatedegreesofreliabilityandinaneconomicalway:

Sustainallactionsandinfluenceslikelytooccurduringexecutionanduse.

Meetthespecifiedserviceabilityrequirementsforastructureorastructuralmember.

Itshouldbedesignedtohaveadequatestructuralresistance,serviceabilityanddurability.

Astructureshouldbedesignedandexecutedinsuchawaythatitwillnotbedamagedbyevents

suchasexplosion,impactandtheconsequencesofhumanerrors,toanextentdisproportionate

totheoriginalcause.

Avoidance of damage

Potentialdamageshouldbeavoidedorlimitedbyappropriatechoiceofoneormoreofthe

following:

Avoiding,eliminatingorreducingthehazardstowhichthestructurecanbesubjected.

Selectingastructuralformwhichhaslowsensitivitytothehazardsconsidered.

Selectingastructuralformanddesignthatcansurviveadequatelytheaccidentalremoval

ofanindividualstructuralmemberoralimitedpartofthestructureortheoccurrenceof

localiseddamage.

Avoidingasfaraspossiblestructuralsystemsthatcancollapsewithoutwarning.

Tyingthestructuralmemberstogether.

Limit states principles

BSEN1990impliesthatthedesignshouldbeverifiedusinglimitstatesprinciples.

Anindicativevalueof120yearsisgivenintheUKNationalAnnexforthedesignworking

lifeofbridges.ItcangenerallybeassumedthattheguidancegiveninBS8500

[

8

]

foratleast

a100-year'intendedworkinglife'willbeappropriateforan'indicativedesignworkinglife'

of120years.

BS EN 1990

2.1(1), (2) & (4)

BS EN 1990

1.1.1(1)

BS EN 1992-1-1

1.1.1(3)

BS EN 1990

2.1(5)

BS EN 1990

3.1(1)

BS EN 1990

2.3 & NA

2

2.1

2.2

2.2.1

2.2.2

2.2.3

4

Limit state design

Limit states are states beyond which the structure no longer fulfils the relevant

designcriteria:

Ultimatelimitstates(ULS)areassociatedwithcollapseorotherformsofstructural

failure.

Serviceabilitylimitstates(SLS)correspondtoconditionsbeyondwhichspecifiedservice

requirementsarenolongermet.

Limitstatesshouldbeverifiedinallrelevantdesignsituationsselected,takingintoaccount

thecircumstancesunderwhichthestructureisrequiredtofulfilitsfunction.

Design situations

Normally,innon-seismiczones,thefollowingdesignsituationsshouldbeconsidered:

Persistentsituationswhichrefertotheconditionsofnormaluse.

Transientsituationswhichrefertotemporaryconditions,suchasduringexecutionorrepair.

Accidentalsituationswhichrefertoexceptionalconditionsapplicabletothestructureorto

itsexposuree.g.fire,explosion,impactortheconsequencesoflocalisedfailure.

Actions

Actionsrefertoasetofforces(loads)appliedtothestructure(directaction),ortoasetof

imposeddeformationsoraccelerationscaused,forexample,bytemperaturechanges,moisture

variation,unevensettlementorearthquakes(indirectaction).

Permanentactionsrefertoactionsforwhichthevariationinmagnitudewithtimeis

negligible.

Variableactionsareactionsforwhichthevariationinmagnitudewithtimeisnot

negligible.

Accidentalactionsareactionsofshortdurationbutofsignificantmagnitudethatare

unlikelytooccuronagivenstructureduringthedesignworkinglife.

Thecharacteristicvalue,

k

,ofanactionisitsmainrepresentativevalueandshallbespecifiedby:

Ameanvalue

–generallyusedforpermanentactions.

Anuppervalue

withanintendedprobabilityofnotbeingexceeded

orlowervalue

withanintendedprobabilityofbeingachieved–normallyusedforvariableactionswith

knownstatisticaldistributions,suchaswindorsnow.

Anominalvalue

–

usedforsomevariableandaccidentalactions.

ThevaluesofactionsgiveninthevariouspartsofBSEN1991:

[

9

]

are

takenascharacteristicvalues.

Verification

Verification,usingthepartialfactormethod,isdetailedinBSEN1990

[

4

]

.Inthismethoditis

verifiedthat,inallrelevantdesignsituations,norelevantlimitstateisexceededwhendesign

valuesforactionsandresistancesareusedinthedesignmodels.

BS EN 1990

3.1 & 3.4

BS EN 1990

3.2

BS EN 1990

1.5.3.1

BS EN 1990

1.5.3.3

BS EN 1990

1.5.3.4

BS EN 1990

1.5.3.5

BS EN 1990

4.1.2(1)

BS EN 1990

BS EN 1991

2.3

2.3.1

2.3.2

2.3.3

5

BasisofdesignBasisofdesign

Design values of actions

Thedesignvalue,

d

,ofanaction,,canbeexpressedingeneraltermsas

d

=g

F

c

k

where

g

F

=partialfactorfortheactionwhichtakesaccountofthepossibilityofunfavourable

deviationsoftheactionvaluesfromtherepresentativevalues.

c =afactorfortheaction

c canhavethevalue1.0,c

0

orc

1

orc

2

whichisusedtoobtainthecharacteristic,

combination,frequentandquasi-permanentvaluesrespectively.Itadjuststhevalue

oftheactiontoaccountforthejointprobabilityoftheactionsoccurringsimultaneously.

SeeTables2.1to2.3whicharederivedfromBSEN1990anditsNationalAnnex

[

7a

]

.

k

= characteristicvalueofanaction.

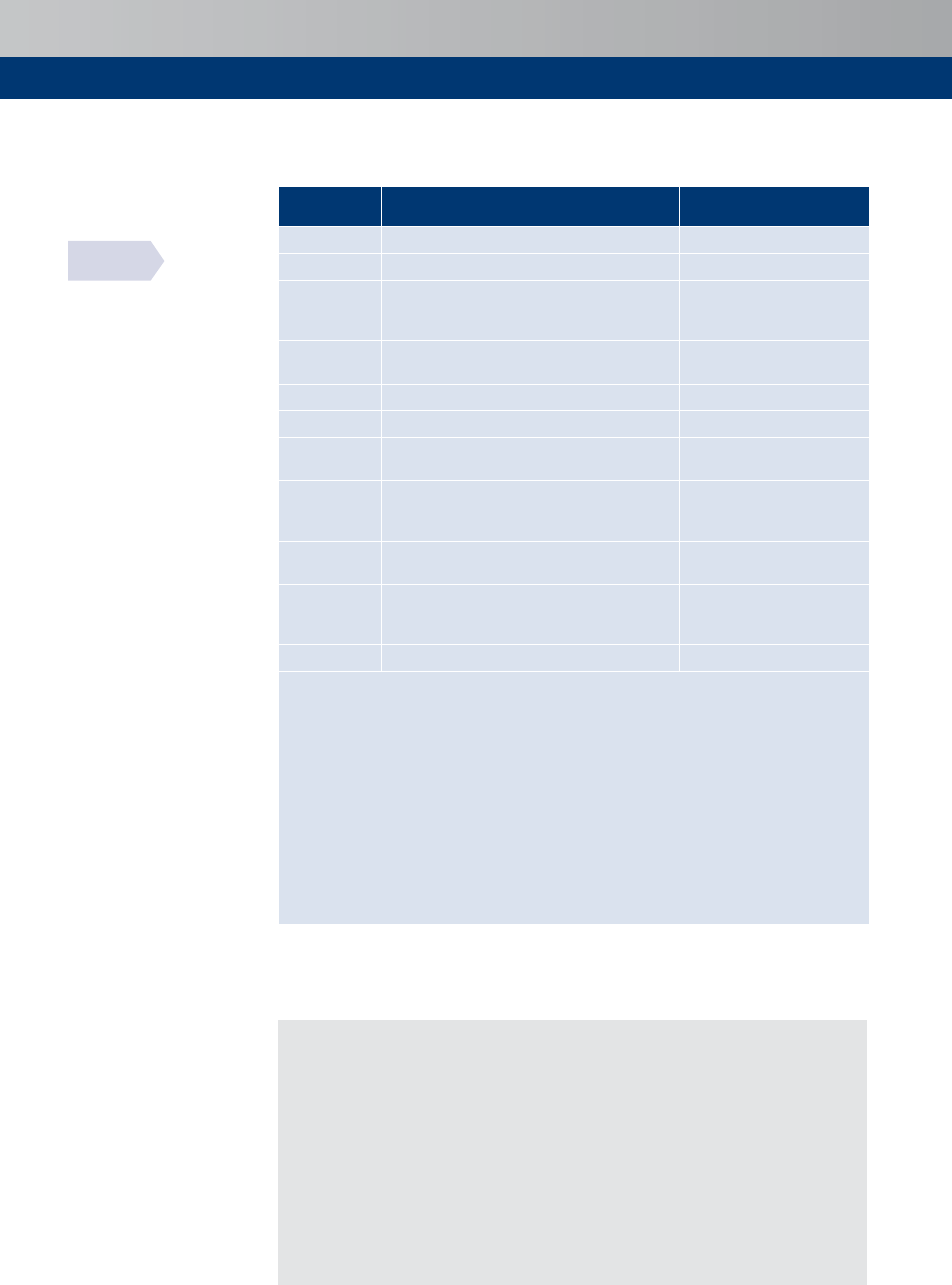

Table 2.1

Values of

c factors for road bridges

Action Symbol c

0

c

1

c

2

Traffic loads (see

BS EN 1991-2,

table 4.4)

gr1a

a

TS 0.75 0.75 0

UDL

0.75 0.75 0

Pedestrianandcycle-trackloads

b

0.40 0.40 0

gr1b

a

Singleaxle 0 0.75 0

gr2 Horizontalforces

0 0 0

gr3 Pedestrianloads

0 0.40 0

gr4 Crowdloading

0 0.75 0

gr5

c

VerticalforcesfromSVandSOVVehicles 0 1.0 0

Wind forces

Persistentdesignsituations

0.50 0.20 0

Duringexecution

0.80 – 0

Duringexecution 1.0 – 0

Thermal actions

0.60

d

0.60 0.50

Snow loads

(duringexecution) 0.80 – –

Construction loads

1.0 – 1.0

Key

a Thevaluesof

c

0

,c

1

andc

2

forgr1aandgr1baregivenforroadtrafficcorrespondingtoadjusting

factorsa

Qi

,a

qi

,a

qr

andb

Q

=1

b Thevalueofthepedestrianandcycle-trackload,giveninTable4.4aofEN1991-2,isa'reduced'value

accompanyingthecharacteristicvalueofLM1andshouldnotbefactoredagainby

c

1

.However,when

gr1aiscombinedwithleadingnon-trafficactions,thisvalueshouldbefactoredbyc

0

c InaccordancewithBSEN1991-2Cl.4.5.2,thefrequentvalueofgr5doesnotneedtobeconsidered.

d The

c

0

valueforthermalactionsmayinmostcasesbereducedto0forultimatelimitstatesEQU,STRand

GEO

Table 2.2

Values of

c factors for footbridges

Action Symbol c

0

c

1

c

2

Traffic loads

gr1

0.4 0.4 0

fwk

0 0 0

gr2

0 0 0

Wind forces

Wk

0.3 0.2 0

Thermal actions

k

0.6

a

0.6 0.5

Snow loads

Sn,k

(duringexecution)

0.8 – 0

Construction loads

c

1.0 – 1.0

Key

a The

c

0

valueforthermalactionsmayinmostcasesbereducedto0forultimatelimitstatesEQU,STR

andGEO

BS EN 1990 NA

table NA. A.2.1

BS EN 1990 NA

table NA. A.2.2

2.3.4

BS EN 1990

6.3.1

6

Table 2.3

Values of

c factors for railway bridges

Actions c

0

c

1

c

2

a

Individual

components of

traffic actions

b

LM71 0.80

c

0

SW/0

0.80

c

0

SW/2

0 1.00 0

Unloadedtrain

1.00 – –

HSLM

1.00 1.00 0

Trackingandbraking

Centrifugalforces

Interactionforcesduetodeformationunderverticaltrafficloads

Individualcomponentsoftraffic

actionsindesignsituationswherethe

trafficloadsareconsideredasasingle

(multi-directional)leadingactionand

notasgroupsofloadsshouldusethe

samevaluesofcfactorsasthose

adoptedfortheassociatedvertical

loads

Nosingforces

1.00 0.80 0

Non-publicfootpathsloads

0.80 0.50 0

Realtrains

1.00 1.00 0

Horizontalearthpressureduetotrafficloadsurcharge

0.80

c

0

Aerodynamiceffects

0.80 0.50 0

Main traffic actions

(groups of loads)

gr11(LM71+SW/0) Max.vertical1withmax.longitudinal

0.80 0.80 0

gr12(LM71+SW/0) Max.vertical2withmax.transverse

gr13(Braking/traction) Max.longitudinal

gr14(Centrifugal/nosing) Max.lateral

gr15(Unloadedtrain) Lateralstabilitywith'unloadedtrain'

gr16(SW/2) SW/2withmax.longitudinal

gr17(SW/2) SW/2withmax.transverse

gr21(LM71+SW/0) Max.vertical1withmax.longitudinal

0.80 0.70 0

gr22(LM71+SW/0) Max.vertical2withmax.transverse

gr23(Braking/traction) Max.longitudinal

gr24(Centrifugal/nosing) Max.lateral

gr26(SW/2) SW/2withmax.longitudinal

gr27(SW/2) SW/2withmax.transverse

gr31(LM71+SW/0) Additionalloadcases

0.80 0.60 0

Other operating

actions

Aerodynamiceffects

0.80 0.50 0

Generalmaintenanceloadingfornon-publicfootpaths

0.80 0.50 0

Wind forces

d

0.75 0.50 0

1.00 0 0

Thermal actions

e

0.60 0.60 0.50

Snow loads

(duringexecution) 0.80 – 0

Construction loads

1.00 – 1.00

Key

a Ifdeformationisbeingconsideredforpersistentandtransientdesignsituations,

c

2

shouldbetakenequalto1.00forrailtrafficactions.

Forseismicdesignsituations,seeTableNAA2.5ofBSEN1990NA

b Minimumcoexistantfavourableverticalloadwithindividualcomponentsofrailtrafficactions(e.g.centrifugal,tractionorbraking)is

0.5LM71,etc.

c

0.8

if1trackonlyisloaded

0.7

if2tracksaresimultaneouslyloaded

0.6

if3ormoretracksaresimultaneouslyloaded

d Whenwindforcesactsimultaneouslywithtrafficactions,thewindforce

c

0

Wk

shouldbetakenasnogreaterthan

W

(seeBSEN1991-1-4).SeeA2.2.4(4)ofBSEN1990

e SeeBSEN1991-1-5

BS EN 1990

table A.2.3

7

BasisofdesignBasisofdesign

Combinations of actions

Ultimate limit states

Thefollowingultimatelimitstatesshallbeverifiedasrelevant:

EQU Lossofstaticequilibriumofthestructureoranypartofitconsideredasarigidbody.

STR Internalfailureorexcessivedeformationofthestructureorstructuralmembers.

GEO Failureorexcessivedeformationofthestructurewherethestrengthsofsoilorrockare

significantinprovidingresistance.

FAT Fatiguefailureofthestructureorstructuralmembers.

ThepartialfactorsandcombinationsofactionsfortheselimitstatesaregiveninTables2.4

to2.7.

Table 2.4

Recommended partial factors

Action EQU (Set A) STR/GEO (Set B) STR/GEO (Set C)

Permanent actions

g

G,sup

g

G,inf

g

G,sup

g

G,inf

g

G,sup

g

G,inf

Concrete self-weight

1.05 0.95 1.35 0.95 1.00 1.00

Steel self-weight

1.05 0.95 1.20 0.95 1.00 1.00

Superimposed dead

a

1.05 0.95 1.20 0.95 1.00 1.00

Road surfacing

a

1.05 0.95 1.20 0.95 1.00 1.00

Weight of soil

1.05 0.95 1.35 0.95 1.00 1.00

Self-weight of other

materials listed in BS EN

1991-1-1, tables A.1-A.6

1.05 0.95 1.35 0.95 1.00 1.00

Creep and shrinkage

– –

1.20 0 1.00 0

Settlement (linear

structural analysis)

– –

1.20 0 1.00 0

Settlement (non-linear

structural analysis)

– –

1.35 0 1.00 0

Variable actions (

g

Q

) Unfavourable Favourable Unfavourable Favourable Unfavourable Favourable

Road traffic actions

(gr1a, gr1b, gr2, gr5, gr6)

1.35 0 1.35 0 1.15 0

Pedestrian actions

(gr3, gr4)

1.35 0 1.35 0 1.15 0

Rail traffic actions

(LM71, SW/0, HSLM)

1.45 0 1.45 0 1.25 0

Rail traffic actions (SW/2

and other load models

representing controlled

exceptional traffic)

1.40 0 1.40 0 1.20 0

Rail traffic actions

(real trains)

1.70 0 1.70 0 1.45 0

Wind actions

1.70 0 1.70 0 1.45 0

Thermal actions

1.55 0 1.55 0 1.30 0

Key

a SeeTableNA.1ofBSEN1991-1-1

[9]

forguidanceonthicknessesforballast,waterproofing,surfacesandothercoatings.

Note

Fordesignvaluesforself-weightofwater,groundwaterpressureandearthpressuresrefertoBSEN1997-1.

BS EN 1990

6.4.1

2.3.5

BS EN 1990 tables

NA.A.2.4(A), (B) & (C)

8

Table 2.7

Combinations of fatigue actions

Action Permanent actions Prestress Leading variable

action

Accompanying

variable actions

Fatigue

action

Favourable Unfavourable

Non-cyclic

k,j,inf

k,j,sup

c

1,1

k,1

c

2,i

k,i

–

Cyclic

k,j,inf

k,j,sup

c

1,1

k,1

c

2,i

k,i

fat

Serviceability limit states

ThecombinationsofactionsfortheserviceabilitylimitstatearegiveninTable2.8.

Table 2.8

Combinations of actions for the serviceability limit state

Combination Permanent actions Prestress Variable actions

Favourable Unfavourable

Leading Others

Characteristic

k,j,sup

k,j,inf

k,1

c

0,i

k,i

Frequent

k,j,sup

k,j,inf

c

1,1

k,1

c

2,i

k,i

Quasi-permanent

k,j,sup

k,j,inf

c

2,1

k,1

c

2,i

k,i

Actions to consider

Thermaleffects,differentialsettlements/movements,creepandshrinkageshouldbetakeninto

accountwhencheckingserviceabilitylimitstates.

Thermaleffects,differentialsettlements/movements,creepandshrinkageshouldbeconsidered

forultimatelimitstatesonlywheretheyaresignificant(e.g.fatigueconditions,intheverification

ofstabilitywheresecondordereffectsareofimportance,etc.).Inothercasestheyneednotbe

considered,providedthattheductilityandrotationcapacityoftheelementsaresufficient.

Wherethermaleffectsaretakenintoaccounttheyshouldbeconsideredasvariableactionsand

appliedwithapartialfactorandcfactor,whichcanbedeterminedfromBSEN1990AnnexA2.

2.3.6

Table 2.5

Combinations of actions for EQU, STR and GEO limit states

Persistent and

transient design

situation

Permanent actions Prestress Leading variable

action

Accompanying

variable actions

Unfavourable Favourable

Exp. (6.10)

g

G,sup

kj,sup

g

G,inf

kj,inf

g

P

g

,1

k,1

g

,i

c

0,i

k,i

Note

ForpartialfactorsseeTable2.4(exceptseeTable2.9forg

P

)

Table 2.6

Combinations for accidental situations

Accidental

design

situation

Permanent actions Prestress Accidental

action

Accompanying variable actions

Unfavourable Favourable Main Others

Exp. (6.11a/b)

k,j,sup

k,j,inf

d

c

1,1

k,1

c

2,i

k,i

BS EN 1992-1-1

2.3.1.2(3)

BS EN 1990

table A2.5

BS EN 1992-1-1

6.8.3

BS EN 1990

table A2.6

BS EN 1992-1-1

2.3.1.2, 2.3.1.3

& 2.3.2.2

BS EN 1990

tables NA.A.2.4(A),

(B) & (C)

9

Basisofdesign

Differentialsettlements/movementsofthestructureduetosoilsubsidenceshouldbeclassified

asapermanentaction,

set

whichisintroducedassuchincombinationsofactions.Apartial

safetyfactorforsettlementeffectsshouldbeapplied.

When creep is taken into account its design effects should be evaluated under the quasi-

permanentcombinationofactionsirrespectiveofthedesignsituationconsideredi.e.persistent,

transientoraccidental.Inmostcasestheeffectsofcreepmaybeevaluatedunderpermanent

loadsandthemeanvalueofprestress.

Thedesignvaluesforvehicleimpactsonsupportingstructuresandsubstructuresaregivenin

BSEN1991-1-1

[9]

section4.3.Thedeisgnvaluesforvehicleimpactsonparapetsaregivenin

BSEN1991-2

[9]

section4.8.

AppropriatevaluesforpartialactionsaregiveninTable2.9

Table 2.9

Values for partial factors applied to actions

Action Ultimate limit state Servicability limit state

STR/GEO EQU FAT Favourable Unfavourable

Favourable Unfavourable Favourable Unfavourable

Shrinkage

g

SH

=0 g

SH

=1.0

– – – – –

Prestress

effects

g

P,fav

=0.9 g

P,unfav

=1.1 g

P,fav

=0.9 g

P,unfav

=1.2

–

inf

=1.0

sup

=1.0

Fatigue – – – –

g

F,fat

=1.0

– –

Material properties

Material properties are specified in terms of their characteristic values, which in general

correspond to a defined fractile of an assumed statistical distribution of the property

considered(usuallythelower5%fractile).

Thevaluesofg

C

andg

S

,partialfactorsformaterials,areindicatedinTable2.10.

Table 2.10

Partial factors for materials

Design situation

g

C

– concrete g

S

– reinforcing steel g

S

– prestressing steel

ULS – Persistent and transient

1.50 1.15 1.15

Accidental

1.20 1.00 1.00

Fatigue

1.50 1.15 1.15

SLS

1.00 1.00 1.00

Assumptions

InadditiontotheassumptionsinBSEN1990,itisassumedthat:

Structuresaredesignedbyappropriatelyqualifiedandexperiencedpersonnel.

Adequatesupervisionandqualitycontrolisprovided.

Constructioniscarriedoutbypersonnelhavingtheappropriateskillandexperience.

MaterialsandproductswillbeusedasspecifiedinEurocode2orintherelevantmaterialor

productspecifications.

Thestructurewillbeadequatelymaintainedandwillbeusedinaccordancewiththe

designbrief.

TherequirementsforexecutionandworkmanshipgiveninENV13670

[10]

arecompliedwith.

2.3.7

2.4

BS EN 1992-1-1

2.3.1.3(1) & (4)

BS EN 1992-1-1

2.3.2.2(3)

BS EN 1992-1-1

2.4.2.4(1) & NA

BS EN 1992-1-1

table 2.1 N & NA

BS EN 1992-1-1

1.3

10

2.5

AtthetimeofwritingBSEN13670

[11]

isexpectedtobepublishedinlate2009,andwill

replace ENV 13670.Oncepublished itis anticipated that standardspecifications will be

updatedtorefertoit.Intheinterimexistingspecificationsshouldbeadapted.

Foundation design

ThedesignofconcretefoundationsissubjecttoEurocode7

[

12

]

forthegeotechnicalaspects

andtoEurocode2forthestructuralconcretedesign.Furtherguidanceonthegeotechnical

designcanbefoundinPD6694-1

[13]

.

Eurocode7iswiderangingandprovidesalltherequirementsforgeotechnicaldesign.Itstates

thatnolimitstatee.g.equilibrium,stability,strengthorserviceability,asdefinedbyBSEN1990,

shallbeexceeded.TherequirementsforULSandSLSdesignmaybeaccomplishedbyusing,

inanappropriatemanner,thefollowingaloneorincombination:

Calculations.

Prescriptivemeasures.

Testing.

Observationalmethods.

The foundation design and the derivation of design resistance are covered by the

GeotechnicalDesign Report.Forsimplestructures,this reportcanbecombined withthe

ground investigation report but it is still a distinct requirement. Both the ULS and SLS

conditionsmustbemetbutthe definitionoftheSLScriteriaisnotpossiblewithout the

liaisonwiththebridgedesignerandafullEurocode7compatibledesigncannotbecarried

outbyapartyinisolationfromtherestofthestructuredesignteam.

BS EN 1997

2.1(4)

BS EN 1997

2.4.6.4

11

Materials

BS EN 1992-1-1

3.1.2(1)

BS EN 1992-1-1

4.4.1.2(5) & NA

BS EN 1992-1-1

table 3.1

BS EN 1992-2

3.1.2 (102) & NA

BS EN 1992-1-1

3.1.2 (2) & NA

BS EN 1992-1-1

3.1.6(1) & NA

BS EN 1992-1-1

3.1.3(4)

BS EN 1992-1-1

3.1.3(5)

3

3.1

3.1.1

Materials

Concrete

Strength and other properties

The compressive strength is denoted by concrete strength classes which relate to the

characteristic(5%)cylinderstrength

ck

,orthecubestrength

ck,cube

,inaccordancewithBSEN

206-1

[

14

]

.

IntheUK,BS8500

[

8

]

complementsBSEN206-1andtheguidancegivenintheformershould

befollowed.

ConcretestrengthclassesandpropertiesareshowninTable 3.1.Inthenotationusedfor

compressivestrengthclass,‘C’referstonormalweightconcrete,thefirstnumberrefersto

thecylinderstrength

ck

andthesecondtocubestrength

ck,cube

.

Thestrengthclasses(C)inBSEN1992-2aredenotedbythecharacteristiccylinderstrength

ck

determinedat 28dayswith a minimumvalueofC25/30 anda maximumvalueofC70/85.

TheshearstrengthofconcreteclasseshigherthanC50/60shouldbedeterminedbytestsor

limitedtothatofC50/60.

Thevalueofthedesigncompressivestrengthofconcrete,

cd

,isdefinedas:

cd

=a

cc

ck

/g

C

where

ck

=characteristiccompressivecylinderstrengthofconcreteat28days

g

C

=partialfactorforconcrete(SeeTable2.9)

a

cc

=acoefficienttakingaccountoflongtermeffectsonthecompressivestrengthandof

unfavourableeffectsresultingfromthewaytheloadisapplied.

IntheUKa

cc

iseither

1.0or0.85dependingonthesituation.Thecorrectvaluesareusedintheappropriate

clausesbelow.Generallyitis1.0forshearand0.85inothercircumstances

Thevalueofconcretedesigntensilestrength

ctd

isdefinedas:

ctd

=

1.0

ctk,0.05

/g

C

where

ctk,0.05

=5%fractilevalueofaxialtensilestrengthofconcrete

Poisson'sratiomaybetakenequalto0.2foruncrackedconcreteand0forcrackedconcrete.

Unlessmoreaccurateinformationisavailable,thelinearcoefficientofthermalexpansionmay

betakenequalto10x10

–6

K

–1

.

Table 3.1

Concrete strength classes and properties

Property Strength class (MPa)

C25/30 C30/37 C35/45 C40/50 C45/55 C50/60 C55/67 C60/75 C70/85 C28/35

a

C32/40

a

f

ck

25 30 35 40 45 50 55 60 70 28 32

f

ck, cube

30 37 45 50 55 60 67 75 85 35 40

f

cm

33 38 43 48 53 58 63 68 78 36 40

f

ctm

2.6 2.9 3.2 3.5 3.8 4.1

4.2

4.4

4.6

2.8 3.0

f

ctk,0.05

1.8 2.0 2.2 2.5 2.7 2.9 3.0

3.1 3.2

1.9 2.1

f

ctk,0.95

3.3 3.8 4.2 4.6 4.9 5.3

5.5 5.7 6.0

3.6 3.9

E

cm,

(GPa)

31 33 34 35 36 37 38 39 41 32 33

Key

aDeriveddata

BS EN 1992-1-1

table 3.1

12

BS EN 1992-1-1

3.1.4(2)

BS EN 1992-1-1

B.1(1)

BS EN 1992-1-1

B.1(2)

Creep

Thecreepcoefficient,h(

0

)isrelatedto

c

,thetangentmodulus,whichmaybetakenas

1.05

cm

.

Thecreepcoefficienth(

0

)maybeobtainedfromFigure3.1ofBSEN1992-1-1,orcalculatedfrom:

h(

0

)=h

0

b

c

(

0

)

where

h

0

=notionalcreepcoefficientandmaybeestimatedfrom:

= h

RH

b(

cm

)b (

0

)

where

h

RH

= factortoallowfortheeffectofrelativehumidityonthenotionalcreep

coefficient:

=

1+

1–/100

for

cm

≤35MPa

0.1

0

1/3

=

[

1+

a

1

(1–/100)

]

a

2

for

cm

>35MPa

0.1

0

1/3

=relativehumidityoftheambientenvironmentin%

b (

cm

) =factortoallowfortheeffectofconcretestrengthonthenotionalcreep

coefficient

=16.8/

cm

0.5

cm

=meancompressivestrengthofconcreteinMPaattheageof28days

b(

0

) =factortoallowfortheeffectofconcreteageatloadingonthenotionalcreep

coefficient

=1/(0.1+

0

0.20

)

0

=notionalsizeofthememberinmm

=2

c

/

c

=cross-sectionalarea

=perimeterofthememberincontactwiththeatmosphere

b

c

(,

0

)=coefficienttodescribethedevelopmentofcreepwithtimeafter

loading

=[(

0

)/(b

H

+

0

)]

0.3

where

=ageofconcreteindaysatthemomentconsidered

0

=ageofconcreteatloadingindays

0

=non-adjusteddurationofloadingindays

b

H

=coefficient depending on the relative humidity ( in %) and the

notionalmembersize(

0

inmm)

=1.5[1+(0.012)

18

]

0

+250≤1500for

cm

≤35MPa

=1.5[1+(0.012)

18

]

0

+250a

3

≤1500a

3

for

cm

>35MPa

a

1

=(35/

cm

)

0.7

a

2

=(35/

cm

)

0.2

a

3

=(35/

cm

)

0.5

Theeffectoftypeofcementonthecreepcoefficientofconcretemaybetakeninto

accountbymodifyingtheageofloading

0

accordingtothefollowingExpression:

0

=

0,T

(9/(2+

0,T

1.2

)+1)

a

≥0.5

where

0,T

=temperatureadjustedageofconcreteatloadingindays(seebelow)

a =powerwhichdependsontypeofcement

=-1forcementClassS(cementClassCEM32.5N)

=0forcementClassN(cementClasses32.5R&CEM42.5N)

=1forcementClassR(cementClassesCEM42.5R,CEM52.5N&CEM52.5R)

3.1.2

13

Materials

CementclassescanbespecifiedusingBSEN197-1

[15]

.WherethecementClassisnotknown,

generally Class R may be assumed.Where the ground granulated blastfurnace slag (ggbs)

contentexceeds35%ortheflyashcontentexceeds20%ofthecementcombination,ClassN

maybeassumed.Whereggbsexceeds65%orpfaexceeds35%,ClassSmaybeassumed.

Theeffectofelevatedorreducedtemperatureswithintherange0–80°Conthematurityof

concretemaybetakenintoaccountbyadjustingtheconcreteageaccordingtothefollowing

Expression:

T

=Se

–(4000/[273+(

D

i

)]–13.65)

D

=1

where

T

=temperature-adjustedconcreteagewhichreplacesinthecorrespondingequations

(D

i

) =temperaturein°CduringthetimeperiodD

i

D

i

=numberofdayswhereatemperatureprevails

The mean coefficient of variation of the above predicted creep data, deduced from a

computeriseddatabankoflaboratorytestresults,isoftheorderof20%.

Thecreepdeformationofconcretee

cc

(∞,

0

)attime=∞foraconstantcompressivestresss

c

appliedattheconcreteage

0

,isgivenby:

e

cc

(∞,

0

)=h(∞,

0

)(s

c

/

c

)

Whenthecompressivestressofconcreteatanage

0

exceedsthevalue0.45

ck

(

0

)thencreep

non-linearityshouldbeconsidered.Suchahighstresscanoccurasaresultofpretensioning,e.g.

in precast concrete members at tendon level. In such cases the non-linear notional creep

coefficientshouldbeobtainedasfollows:

h

nl

(∞,

0

)=h(∞,

0

)exp[1.5(

s

–0.45)]

where

h

nl

(∞,

0

)=non-linearnotionalcreepcoefficient,whichreplacesh(∞,

0

)

s

=stress–strengthratios

c

/

ck

(

0

)

s

c

=compressivestress

ck

(

0

) =characteristicconcretecompressivestrengthatthetimeofloading

Shrinkage

Thetotalshrinkagestrainiscomposedoftwocomponents,thedryingshrinkagestrainandthe

autogenousshrinkagestrain.Thedryingshrinkagestraindevelopsslowly,sinceitisafunctionof

the migration ofthe waterthrough thehardened concrete.The autogenous shrinkage strain

developsduringhardeningoftheconcrete:themajorpartthereforedevelopsintheearlydays

aftercasting.Autogenousshrinkageisalinearfunctionoftheconcretestrength.Itshouldbe

consideredspecificallywhennewconcreteiscastagainsthardenedconcrete.

Hencethevaluesofthetotalshrinkagestrainfollowfrom:

e

cs

=e

cd

+e

ca

where

e

cs

=totalshrinkagestrain

e

cd

=dryingshrinkagestrain(seeTable3.2)

e

ca

=autogenousshrinkagestrain(seeTable3.2)

Steel reinforcement

ThepropertiesofsteelreinforcementtoBS4449:2005

[16]

areshowninTable3.3.ThisBritish

StandardcomplementsBSEN10080

[17]

andAnnexCofBSEN1992-1-1.

AnnexCallowsforastrengthrangebetween400and600MPa.BS4449:2005adopts500MPa.

BS EN 1992-1-1

3.1.4(3)

BS EN 1992-1-1

3.1.4(4)

BS EN 1992-1-1

3.1.4(6)

BS EN 1992-1-1

3.2

Materials

BS EN 1992-1-1

B.1(3)

3.1.3

3.2

14

Table 3.2

Long-term (70-year) shrinkage strains

Concrete strength at

28 days (

f

ck

)

Strain due to drying

shrinkage (x 10

3

)

Strain due to autogenous

shrinkage (x 10

3

)

Total shrinkage

strains (x 10

3

)

20

0.517 0.025 0.542

25

0.489 0.038 0.527

30

0.463 0.050 0.513

35

0.438 0.063 0.501

40

0.415 0.075 0.490

45

0.393 0.088 0.481

50

0.372 0.100 0.472

60

0.333 0.125 0.458

70

0.298 0.150 0.448

Notes

1ThevaluesshownassumeClassRcement(ClassNandClassSwillhavelowervalues).

2Thedryingshrinkagevaluesassumeanotionalmembersize,

0

,of150mm.For

0

of300mm

multiplyvaluesby0.81andfor

0

of500mmorgreater,multiplyvaluesby0.75.

Table 3.3

Properties of reinforcement

Property Class

A B C

Characteristic yield strength f

yk

or f

0.2k

(MPa) 500 500 500

Minimum value of k = (f

t

/f

y

)

k

≥1.05 ≥1.08 ≥1.15<1.35

Characteristic strain at maximum force

e

uk

(%) ≥2.5 ≥5.0 ≥7.5

Note

TablederivedfromBSEN1992-1-1AnnexC,BS4449:2005andBSEN10080.Thenomenclatureused

inBS4449:2005differsfromthatusedinAnnexCandusedhere.

ClassBorClassCreinforcementshouldbeused.Forsteelfabricreinforcement,ClassAmayalso

beusedprovideditisnottakenintoaccountintheevaluationoftheultimateresistance.

Prestressing steel

Typicalprestressingstrandpropertiesareshown inTable3.4.The manufacturer’stechnical

datasheetsshouldbereferredfordetailedinformation.

PropertiesofprestressingsteelsshouldbeinaccordancewithEN10138.However,untilthis

standardispublishedBS5896

[18]

maybeused.

The0.1%proofstress(

p0.1k

)andthespecifiedvalueoftensilestrength(

pk

)areusedtodefine

thecharacteristicvaluesoftheprestressingsteels.

Thedesignvaluesfortheprestressingsteelarederivedbydividingthecharacteristicvalues

by the partial safety factor for prestressing steel g

S

. For ultimate limit state verification,

g

S

=1.15forpersistentandtransientdesignsituationsand1.0foraccidentaldesignsituations.

Themodulusofelasticity

p

canbeassumedequalto205GPaforwiresandbarsand195GPa

forstrand.

BS EN 1992-1-1

table C1

BS EN 1992-2

3.2.4 & NA

BS EN 1992-1-1

3.3.6(2) & (3)

BS EN 1992-1-1

3.3.2(1)

BS EN 1992-1-1

3.3.3(1)

3.3

15

MaterialsMaterials

Table 3.4

Dimensions and properties of low relaxation strand and wire for prestressed concrete

Type of

strand

Nominal

diameter

(mm)

Nominal

tensile

strength (MPa)

Steel area

(mm²)

Nominal

mass (g/m)

Characteristic

breaking load

(kN)

Characteristic

0.1% proof

load (kN)

Characteristic

load at 1%

elongation (kN)

7 wire

standard

15.2 1860 139 1090 259 220 228

15.2 1670 139 1090 232 197 204

12.5 1860 93 730 173 147 152

12.5 1770 93 730 164 139 144

11.0 1770 71 557

125

106 110

9.3 1860 52 408 97 82 85

9.3 1770 52 408 92 78 81

7 wire super 15.7 1860 150 1180 279 237 246

15.7 1770 150 1180 265 225 233

12.9 1860 100 785 186 158 163

11.3 1860 75 590 139 118 122

9.6 1860 55 432 102 87 90

8.0 1860 38 298 70 59 61

7 wire drawn 18.0 1770 223 1750 380 323 334

15.2 1820 165 1295 300 255 264

12.7 1860 112 890 209 178 184

Relaxation of prestressing steel

BSEN1992-1-1definesthreeclassesofrelaxation.

Class1:ordinarywireandstrand

Class2:lowrelaxationwireandstrand

Class3:hotrolledandprocessedbars

Thedesigncalculationofthelossesduetorelaxationoftheprestressingsteelshouldbebased

on the lossat 1000 hr (r

1000

) after tensioningat a mean temperature of20°C and initial

prestressof70%(0.7

pk

).Thevaluesofr

1000

canbetakenfromthecertificateorassumedtobe:

Class1–8%

Class2–2.5%

Class3–4%

The relaxation loss may be obtained from manufacturer’s test certificates or they can be

calculated,baseduponthefollowingequations(seealsoTable3.5):

Class1

s

pr

t

r

1000

s

pi

D

5. 39 e

6.7m

10

–5

1000

=

0.75 (1– m)

Class2

s

pr

t

r

1000

s

pi

D

0. 66 e

9.1

m

10

–5

1000

=

0.75 (1– m)

Class3

s

pr

t

r

1000

s

pi

D

1. 98 e

8m

10

–5

1000

=

0.75 (1– m)

where

Ds

pr

=absolutevalueoftherelaxationlossesoftheprestress

s

pi

=absolutevalueoftheinitialprestress

=s

pm0

forpost-tensioning (seeSection11.3.2)

=maximumtensilestressappliedtothetendonminustheimmediatelosses

occurringduringthestressingprocessforpre-tensioning (seeSection11.3.3)

BS EN 1992-1-1

3.3.2(4)

BS EN 1992-1-1

3.3.2(5)

BS EN 1992-1-1

3.3.2(6)

BS EN 1992-1-1

3.3.2(7)

3.3.1

16

=timeaftertensioning(inhours)

=s

pi

pk

,where

pk

isthecharacteristicvalueofthetensilestrengthofthe

prestressingsteel

r

1000

=valueofrelaxationloss(%),at1000hoursaftertensioningandatamean

temperatureof20°C

The long-term (final) values of the relaxation losses may be estimated from = 500,000

hours.

Relaxationlossesareverysensitivetotemperatureofthesteelwhereheattreatmentisapplied

(e.g.bysteam)(seeBSEN1992-1-1Cl.10.3.2.1).Otherwisewherethetemperatureisgreater

than50°C,therelaxationlossesshouldbeverified.

Table 3.5

Relaxation losses based on using Expressions (3.28 to 3.30) in BS EN 1992-1-1

Class

r

1000

(%) μ = s

pi

/

pk

t (hours)

Ds

pr

/s

pi

%

1

8 0.80 500,000 23.3

0.76 21.5

0.72 19.8

0.68 18.2

0.64 16.8

0.60 15.5

2

2.5 0.80 6.1

0.76 5.1

0.72 4.3

0.68 3.6

0.66 3.0

0.60 2.5

3

4 0.80 12.1

0.76 10.6

0.72 9.3

0.68 8.1

0.64 7.1

0.60 6.2

Relaxationlossesaresensitivetovariationsinstresslevelsovertimeandcanthereforebe

reducedbytaking intoconsiderationofother time-dependent losses occurringwithinthe

structureatthesame time(such as creepandshrinkage).PreviousUK practiceistobase

designontherelaxationlossof1000hourswithoutconsideringtheinteractionwithcreep

andshrinkage.

BS EN 1992-1-1

3.3.2(8)

BS EN 1992-1-1

3.3.2(9)

17

Durabilityandcover

Durability and cover

General

A durable structure shall meet the requirements of serviceability, strength and stability

throughoutits designworking life, without significant loss ofutility or excessiveunforeseen

maintenance.

Inordertoachievetherequireddesignworkinglifeofthestructure,adequatemeasuresshallbe

takentoprotecteachstructuralelementagainsttherelevantenvironmentalactions.Exposure

conditionsarechemicalandphysicalconditionstowhichthestructureisexposedinadditionto

mechanicalactions.

Requirementsof durability should be considered at all stages of designand construction,

includingtheselectionofmaterials,constructiondetails,executionandqualitycontrol.

Half-jointsshouldnotbeusedinbridgesunlessthereareadequateprovisionsforinspection

andmaintenance.

Waterpenetrationorthepossibilityofleakagefromthecarriagewayinto

the inside of voided structures should be considered in the design. For concrete surfaces

protectedbywaterproofingtheexposureclassis

XC3

.

Where de-icing salt is used,all exposedconcrete surfaces within

10m

of the carriageway

horizontally or within

5m

above the carriageway should be considered as being directly

affected by de-icing salts. Top surfaces of supports under expansion joints should also be

consideredasbeingdirectlyaffectedbyde-icingsalts.Theexposureclassesforsurfacesdirectly

affectedbyde-icingslatsare

XD3

and

XF2

or

XF4

asappropriate.

Adequatecoverisrequiredtoensuresafetransmissionofbondforces(seeSection4.2)and

protectionofsteelagainstcorrosion(seeSections4.3and4.4).

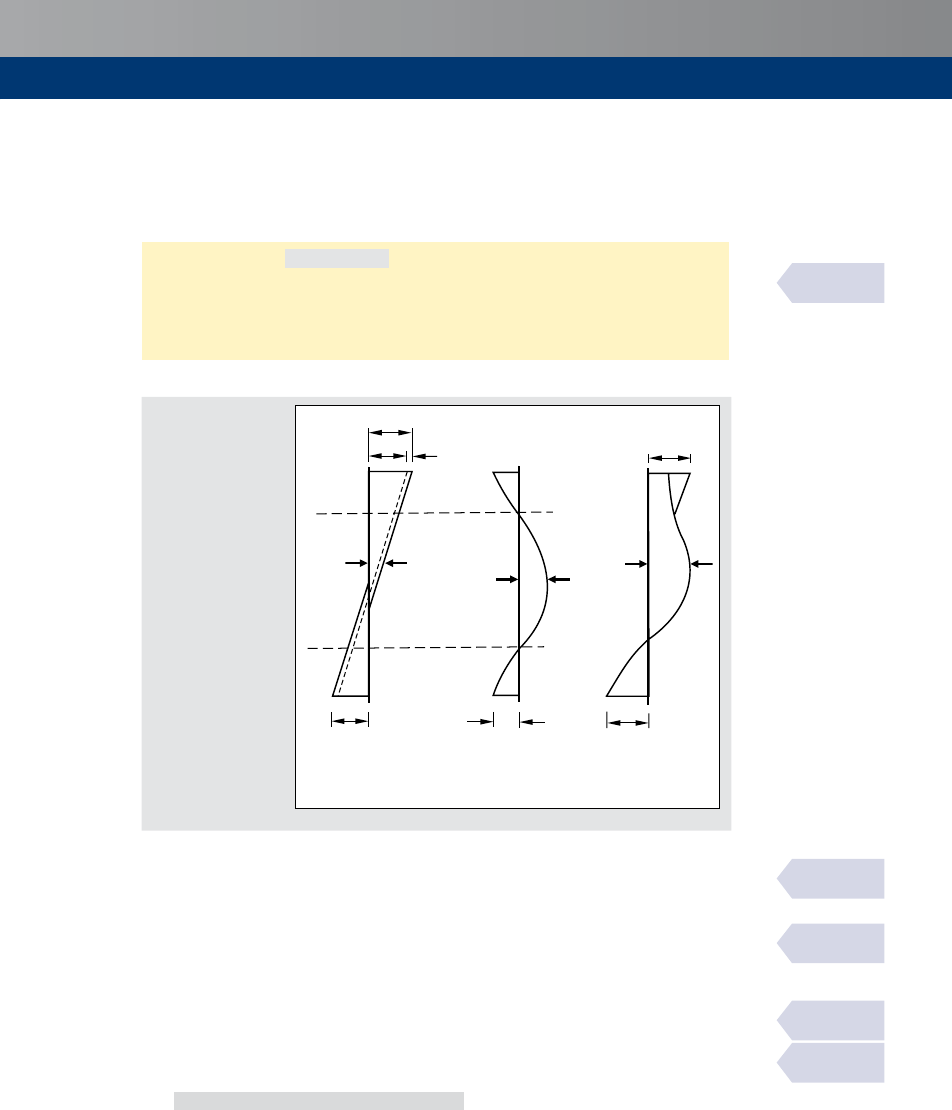

The concrete cover to reinforcement is the distance from the outer surface of the

reinforcementtothenearestconcretesurface.Drawingsshouldspecifythenominalcover.As

illustrated in Figure 4.1, the nominal cover should satisfy the minimum requirements in

respectofbondanddurability,andallowforthedeviationtobeexpectedinexecution(see

Section4.5).

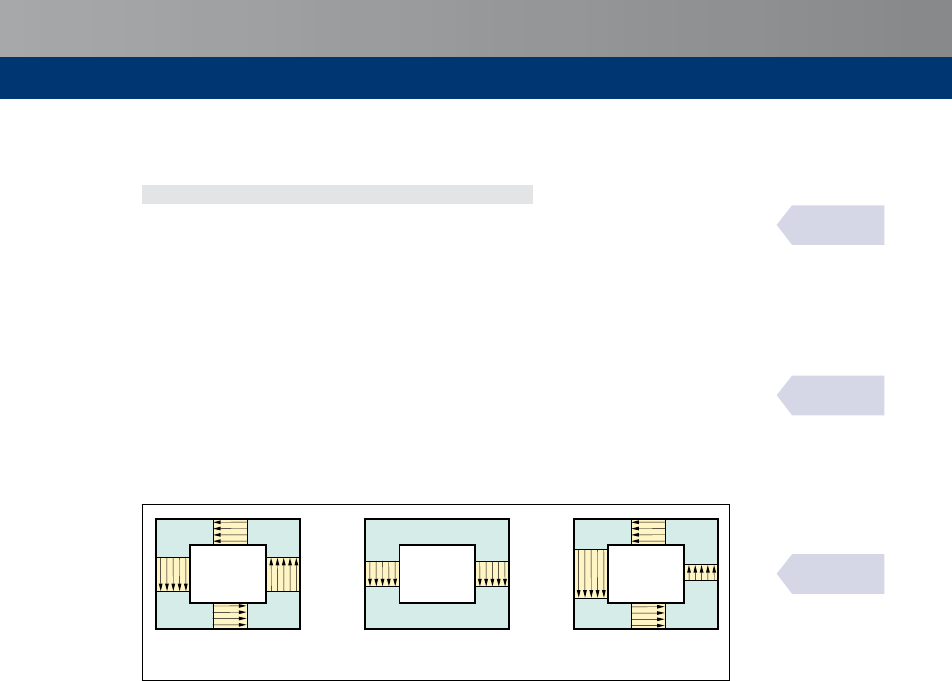

Figure 4.1

Determination

of cover

Nominalcover,

nom

Minimumcover,

min

(forbond,

min,b

or

durability

min,dur

)

Designallowancefor

deviation,D

dev

BS EN 1992-1-1

4.1

BS EN 1992-1-1

4.3(1), 4.2(1)

BS EN 1992-1-1

4.3(2)

BS EN 1992-1-1

4.4.1.2(1)

BS EN 1992-2

4.2(106) & NA

BS EN 1992-1-1

4.4.1.3(3)

BS EN 1992-2

4.2(104), (105)

& NA,

PD 6687-2 5.1

4

4.1

18

Cover for bond, c

min,b

Inordertotransmitbondforcessafelyandtoensureadequatecompaction,theminimumcover

shouldnotbelessthan

min,b

inTable4.1.

Table 4.1

Minimum cover, c

min,b

, requirements for bond

Reinforcement type and arrangement c

min,b

Individual bars

Diameterofbar,

f

Bundled bars

Equivalentdiameterofbars,

f

n

Post-tensioned circular ducts

Diameterofductor80mmwhicheverissmaller

Post-tensioned rectangular ducts

Smallerdimensionorhalfgreaterdimension

whicheverisgreater,butnotmorethan80mm

Pre-tensioned strand or wire

1.5timesthediameter

Pre-tensioned indented wire

2.5timesthediameter

Cover for durability, c

min,dur

Environmentalconditionsare classified accordingtoTable 4.2, whichis basedon BS8500.

Concretecompositionandminimumcoversrequiredfordurabilityindifferentenvironmental

conditionsaresetoutinTable4.3,derivedfromBS8500

[

8

]

.Thesetablesgiverecommendations

fornormalweightconcreteusingmaximumaggregatesizeof20mmforselectedexposure

classesandcovertoreinforcement.

InaccordancewithBS8500,specialattentionshouldbegiventotheconcretecomposition

and aggregates, when considering freeze/thaw attack, chemical attack or abrasion

resistance.

Table 4.2

Exposure Classes

Class Class description Informative example applicable to the United Kingdom

No risk of corrosion or attack (X0 class)

X0 Forconcretewithout

reinforcementorembedded

metalallexposuresexcept

wherethereisfreeze/thaw,

abrasionorchemicalattack.

Unreinforcedconcretesurfacesinsidestructures.Unreinforcedconcretecompletelyburiedinsoil