Store More Apex Shed

4x6 | 8x6 | 12x6 | 16x6 | 20x6

4x8 | 8x8 | 10x8 | 12x8 | 16x8 | 20x8

Adult assembly only

Minimum 2 people

5 Hours building time based

on size and experience

Made in Great

Britain

Store More Garden Buildings Limited,

Edward Merton House, Park Gate Close, Bredbury Park Way, Bredbury Industrial Park, Stockport, Cheshire. SK6 2SZ

Tel: (0161) 430 3347 Fax: (0161) 406 6054 , E-mail: [email protected] , www.shedbaron.co.uk

Building your Shed And Maintenance Troubleshooting & General Advice

Pre-Building Checklist

● Base - Make Sure you have a flat and level base to build on. More Details below

● Walking Space - You should build your shed 2 feet away from any existing

structures or obstructions (such as fences, tree’s, power lines, etc.) This is to

ensure that you have room to get around and care for your shed, but also to

prevent damage over time. Follow recommended maintenance to prevent

damage over time

● Check your parts - Especially important if you are designating a day to build or

hiring a handyman. Check you have all your parts before starting assembly, or

hiring any 3rd party to assemble your building.

Bases

● We recommend you build your shed on a flat, level base with good water

drainage. We would advise checking that no rain pools on your base before you

assemble anything.

● Any level

material,

such as

flagstones

or concrete

is ideal

Recommended Maintenance

● Use a silicone sealant inside & outside of the windows as soon as possible after

assembly to prevent leaks.

● Treat your building after construction & annually with a good quality water

resistant treatment. Follow instructions on your treatment. Take care to cover

all exposed timber, particularly with clear coat treatments

● Trim any overhanging trees or branches. These could peirce windows or felt

and lead to leaking.

● Regularly Check & Replace Damaged Felt to prevent water ingress.

● Use a suitable oil to lubricate any moving parts, such as hinges

Troubleshooting

● Q: I have a missing part. What should I do? A: Firstly check that all of your

building’s parts are there by laying them all out on the ground. Check between

the panels & larger parts as glazing comes banded together & is placed

between the panels, along with the fixing kit, for safer transportation. If they

are still not found please call our support team

● Q: My building seems a little flimsy? A: Your building won’t reach full rigidity

until fully assembled so do not panic.

● Q: Construction seems tricky? A: Take your time & read the instructions

thoroughly. These buildings should be constructed by two people. If in doubt

contact our team for advice.

● Q: My building isn’t going together properly, it is twisted. A: This a common side

effect of an uneven base. Check that your base is level and inspect the panels

are positioned correctly. If still in doubt, contact our team for assistance.

● Q: Why is there a gap around the doors? A: During the year the wood of your

building will shrink & expand, which will create a gap around you building’s

doors. This is natural.

● Q: My building is not water tight around the windows. A: These products have

been designed as an affordable solution to most popular light domestic uses &

we do not state that they are watertight. Use silicon sealant around the

windows to improve the water resistant qualities of the building.

General Advice

● Wood is a natural material, which means that no two boards on your building

will be identical & will expand & contract differently due to moisture levels.

This natural effect of expansion or contraction is inevitable and is compensated

for by the tongues and grooves of the boards or overlap between boards.

Timber in overlap buildings may warp & twist over time, which is a natural

process. The timber may crack naturally over time, but will not affect the

structural integrity of the building provided it has been assembled as advised.

● Please watch out for the following minor blemishes:

- Protruding nails = hammer in the nails so that they are flush with the

wood’s surface.

- Splintered wood and sharp edges = smooth down with sandpaper.

Wear protective gloves & robust clothes during construction to

prevent splinters.

- Loose or dead knots, cracks = use a non-toxic wood glue to secure.

- Some boards have a rough side and a smoother side. Ensure that these

are placed appropriately, i.e. floorboards are smooth side up

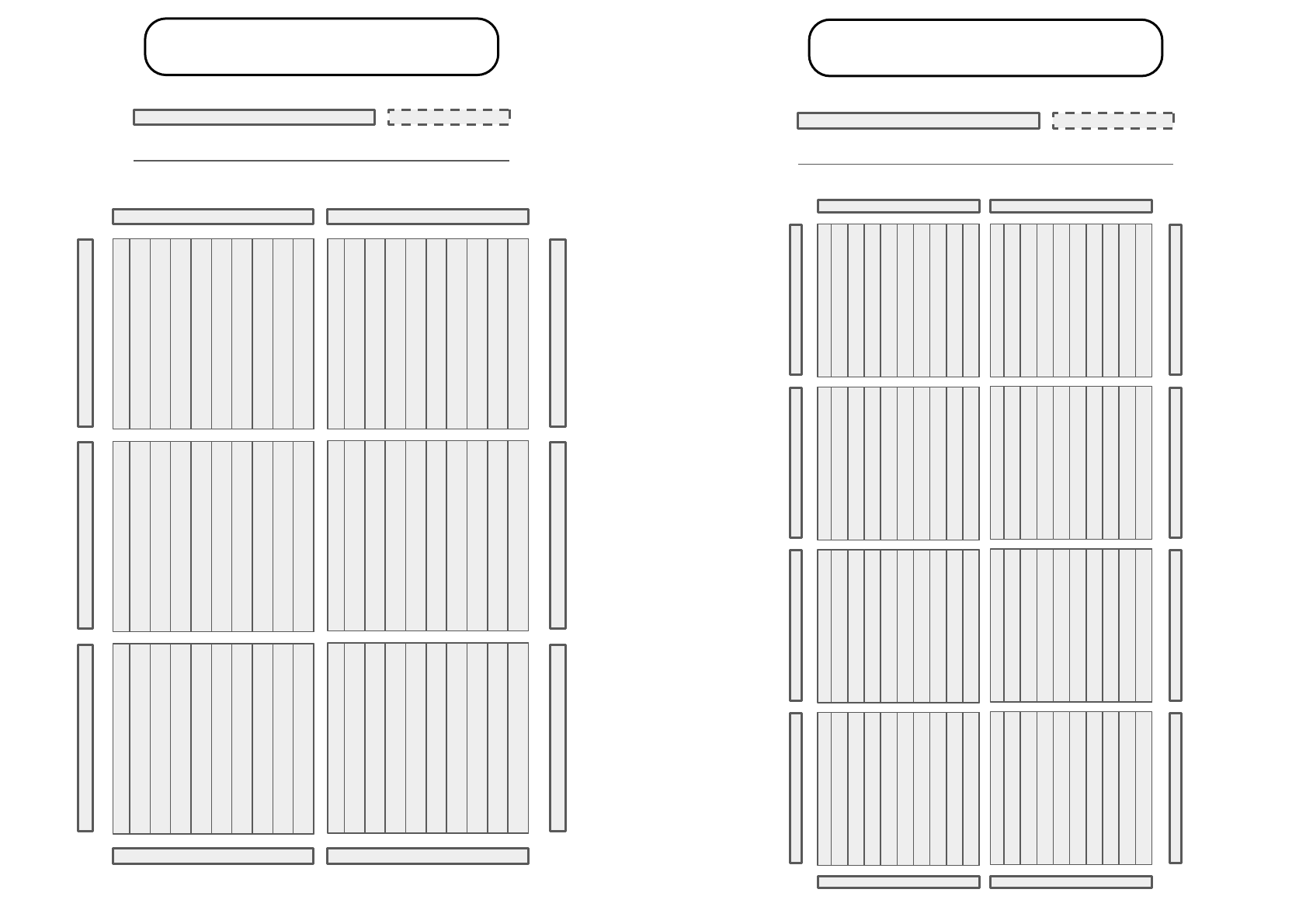

All 4ft Panels are interchangeable with one another to fully

configure your own building

Use the diagrams to plan your buildings layout before you

begin building. Choose a layout for the sides, then select

which panel you would like in each slot

Types of 4ft Panels:

Building Planner - 8x6

Door Panel

Make sure this

Door Panel has

plenty of room

around it to open

your door outwards

so your shed is easy

to access.

Plain Panel

This Plain Panel is

great for protecting

against the

elements and

perfect for being

placed against a

wall, fence or

hedge.

Window

Panel

The Window Panel

means your shed

will be filled with

plenty of natural

light. Use the

modular design to

place this wherever

it will get the most

light each day

4ft Plain / Door / Window

2ft Plain

Building Planner - 12x6

Building Planner - 16x6

4ft Plain / Door / Window

2ft Plain

4ft Plain / Door / Window

2ft Plain

Building Planner - 20x6 Building Planner - 4x6

Building Planner - 4x8

Plain / Door / Window

4ft Plain / Door / Window

2ft Plain

4ft Plain / Door / Window

2ft Plain

Building Planner - 8x8 Building Planner - 10x8

4ft Plain / Door / Window

2ft Plain

4ft Plain / Door / Window

2ft Plain

Building Planner - 12x8 Building Planner - 16x8

4ft Plain / Door / Window

2ft Plain

4ft Plain / Door / Window

2ft Plain

Building Planner - 20x8

4ft Plain / Door / Window

2ft Plain

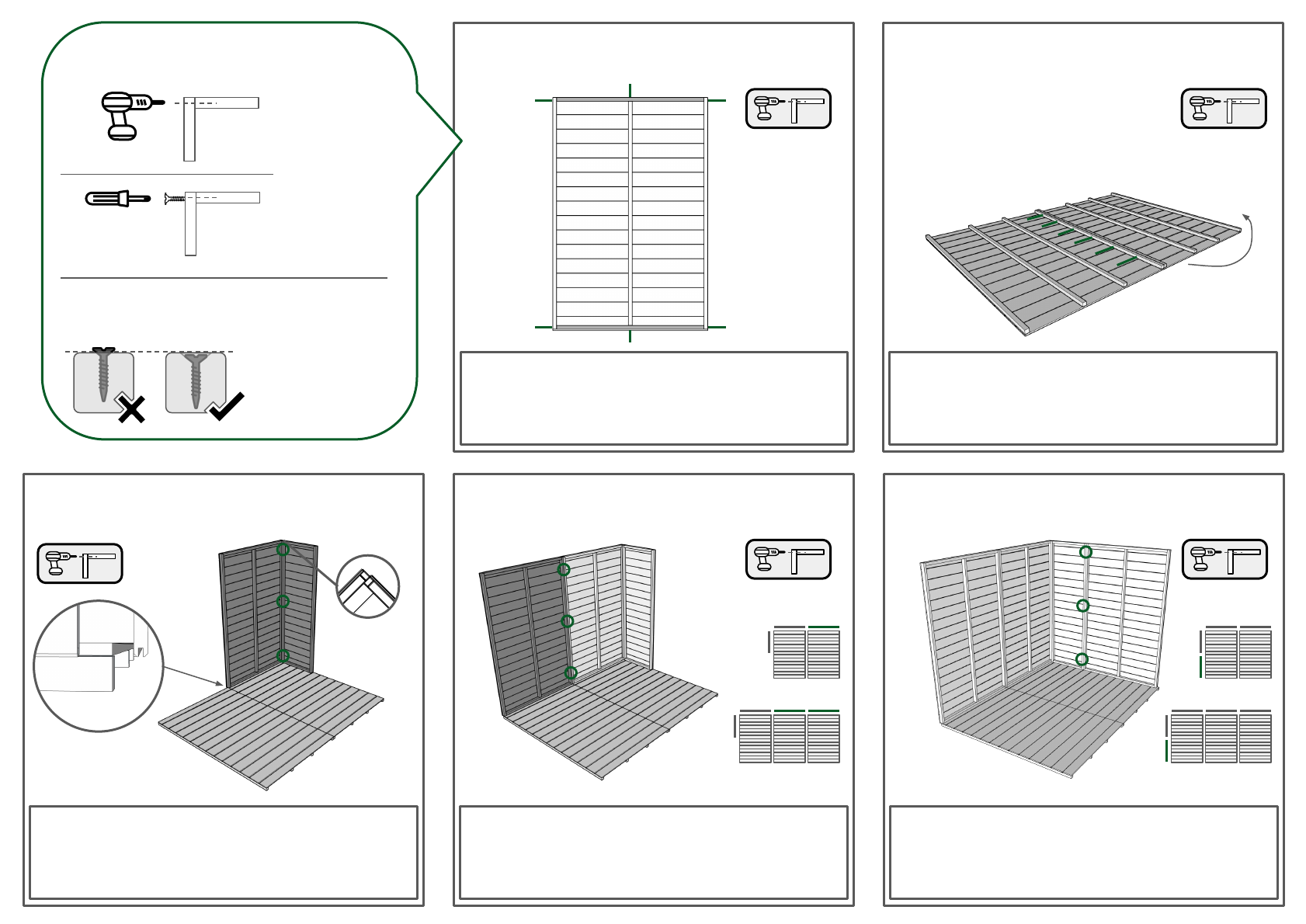

Step

01

Firstly install the top & bottom rails to each of your wall

panels. The length and/or quantity may vary based on

the panel. Affix these as shown, using 50mm Screws.

Pilot drill all screw holes to avoid splitting.

Step

03

Step

05

Use 3x50mm Screws to affix the next side panel. As all

4ft panels are interchangeable your design may vary

here. Follow your building planner to see which panel

should sit her (2ft / 4ft).

Step

04

Use 3x50mm Screws to affix the next back panel.

Follow your building planner to install all panels for this

wall. Once again, all 4ft panels are interchangeable, so

your design may vary here.

Step

02

Next join together your floor sections as shown in your

building planner. Use 50mm Screws to join. If you have an 8ft

deep building, you will need to connect the front and back

sections using the floor blocks. Flip the floor over to continue.

For safety, only flip up to 4 floor sections at once.

8x6

12x6

8x6

12x6

Next, install the back 2 corner panels. These will vary based

on your choice of positions. The panel (2ft / 4ft) along the side

wall will sit in front of the back panel (2ft / 4ft). Use 3x 50mm

Screws. There will be a 17mm gap between the cladding of the

side panel and the floor.

Pilot Drilling Holes

Pilot drill

all screw

holes to

avoid

wood

splitting.

Countersinking Screws

Countersink

all screws to

avoid sharp

edges

Step

06

Now, affix the other side panels. These should be a 2ft &

4ft panel for a 6ft deep building. For an 8ft deep

building, this will be 2x 4ft Panels. Affix together, & to

the back right wall using 50mm Screws as shown.

Step

08

Now the walls are completed you can fix your panels to

the floor. Using 50mm screws, fix each panel to a

bearer, through the floorboards (the nails down the

center of each floor section will help as a guide).

Step

09

Fix the side gable panels to the side wall framing with

50mm screws, as shown. This will line up with the front

of the panel, not the front of the building. Repeat this

step on both sides of the building.

Step

11

Now fix the truss in place on top of the wall panels. Affix

into the blocks using 70mm Screws. Make sure to line

the middle of the truss up where the panels meet. Fix

the purlins using 30mm screws.

Step

10

Build the truss by lining up the angled beams alongside

the angled wooden boards use 30mm screws to secure

in place.

Step

07

In order to finish the 4 walls, fix the front 2 panels in

place, using 50mm Screws at each join. The front panels

will sit in front of the side panels. (12x6 will have 3

panels, 16x6 will have 4, etc.)

8x6

12x6

8x6

12x6

Step

12

To begin installing your roof, first attach a roof board

flush with the front face of your building, as shown. Fix

in place using 2x 30mm Nails at either end & one nail in

the center.

Step

14

Repeat Steps 12-13 on the other side of the roof. Note,

if you have a 12x6 Building, you will need to install the

central roof boards first, then the opposite side boards.

Step

15

To fix the windows in place, position the included sills

along the bottom edge of each window, as shown. This

will be held in place with the glazing in the next step. (If

your building has no windows, skip to 18).

Step

17

Using 30mm Nails, fix the cover stips in place to hold

each of the glazing sections in place. Take care not to

pierce the glazing itself with the nails. Repeat steps

15-17 until all the glazing sheets are held in place.

Step

16

As mentioned, the glazing should be placed in front of

each sill, to hold it in place. Fit your windows centrally

within each opening in order to leave some room

left/right to fix the cover strips.

Step

13

Continue to place & fix roof boards until there is an

overhang at the back. Use 2 Nails at either side.

Step

18

Next, affix the hinges to your doors. These should be

attached in line with the framing on the back of the

doors. Use 4x 30mm Screws per hinge. Next, fix the

door framing as shown, using 30mm screws.

Step

20

Fix the cloaking strip up the center using 30mm Nails

into the framing behind the door. Affix to the side you

want to be the main door. On the same side, affix the

latch to the top of the frame using a 25mm Screw

Step

21

Inside, on the opposite door, fix the 2 door blocks from

the outside using 2x 50mm Screws each. Next use a

25mm Screw to affix the latches, top & bottom

Step

23

Cut your felt to the length of your roof + 140mm. For

this building you will have 3 lengths of felt. Affix the first

length using felt tacks at 100mm intervals along the

dotted line. Use 5 more at the top.

Step

22

To begin fixing the included felt to your building, first

affix the eaves to the back of your building, where the

roof overhangs. Use 3x 30mm Screws for each. Ensure

these are flush left & right of the roof boards.

Step

19

Now fix the doors in place by attaching the hinges to

either side of the door frame. To ensure easy access to

the building, allow for a 2mm gap at either side & a 4mm

gap in the center

2mm

4mm

Step

24

Next fold the sides of this sheet over the edge of your

building and fix down using felt tacks.

Step

26

Affix the 3rd sheet this should overlap both of the side

sheets. At 100mm intervals secure with felt tacks along

the dotted lines. Fold and fix down the sides using tacks

also.

Step

27

Install the Fascia Boards over the top of the Felt to

finish and secure using 30mm nails as shown. This will

also secure any felt that may be resisting being folded

or tacked in place.

Step

29

Congratulations! Your Garden Building is now

complete. To ensure your building lasts for years to

come, retreat annually to prevent damage. Please do

not treat for the first 6 months.

Step

28

Add cloaking strips along any seams in the building to

complete the walls of your building. You will need to cut

some of these to length. Also add the decorative

diamond to cover the facia split line.

Step

25

Repeat steps 23-24 to add the other side. Fix at 100mm

intervals along the dotted line. Use 5 Tacks at the top

and fold the sides down over the edge of the building

and affix with Tacks.

Thank you for purchasing this Store More

product, we hope you will be delighted with

your new building for years to come, and if you

are we’d love for you to leave a review!

If for whatever reason you are not satisfied with

your purchase, you have any queries or you need

any help, call our Product Support Team on

0161 430 3347

shedbaron.co.uk 0161 430 3347

After Market Modification

● We do not recommend modifying this product. However, customers do enjoy modifying their buildings with their

own specific needs in mind as our products allow for a wide range of uses. If you modify this product for your own

personal requirements you are doing so at your own risk.

● Customers who modify their buildings should ensure they do so safely & ensure they do not affect structural

integrity as we will not be held liable for injuries caused as a result of the modification.

● If you are considering modifying this building be aware that any modifications invalidate your warranty & may

affect your consumer rights.

Product Warranty

● Products are built to the highest quality standards & should provide convenient, secure storage for years to come,

this of course being subject to reasonable use, care & transportation.

● If in doubt about the product’s limitations please read & understand all of the instructions & guidance notes. If

necessary please contact the retailer that the item was purchased from.

● Please contact the retailer from which the product was purchased from for warranty & guarantee information.

● Please note, the warranty does not extend to damage caused by post-purchase transportation, careless handling or

damage caused by misuse or modification.

● Treat your building annually with a quality, water resistant timber treatment to comply with the buildings

warranty.